Page 529 - Business Principles and Management

P. 529

Unit 6

Producing the Product

If the new product has survived the research and design process, the company

can begin producing for sale. This is an expensive step. The company may have

to build or remodel its manufacturing facilities. It must purchase raw materials

and hire and train enough employees to produce the product. Then it must pro-

mote, distribute, and sell the product. However, if the company has carefully

planned and produced the product, the product has a better chance of succeed-

ing and earning a profit for the company when customers purchase it.

As you learned in Chapter 1, production is making a product or providing a

service. Manufacturing is a form of production in which raw and semifinished

materials are processed, assembled, or converted into finished products.

Manufacturing is a complex process, even when only one product is pro-

duced. Examine any product you purchased recently. Very likely, it is made of

several parts. The company must either manufacture those parts or purchase

them from other companies. The manufacturer must store the parts until it needs

them. Then people and machinery must assemble the parts. Once assembled, the

product must be packaged. Many products are packed together for shipping and

then stored in a warehouse for delivery to the businesses that will sell them.

In addition to the activities just described, the manufacturing process in-

volves many other tasks. The manufacturer must maintain equipment, purchase

supplies, and train people to operate the equipment. And often, manufacturers

produce many products at the same time.

DIFFERENT TYPES OF MANUFACTURING PROCESSES

When you think of a manufacturing business, you may have an image of a large

factory with a long assembly line. Workers perform specific activities on the as-

sembly line as the product moves past. Many products, all looking exactly alike,

are produced on assembly lines each day. But assembly lines are only one of sev-

eral ways to manufacture products (see Figure 19-2).

MASS PRODUCTION Mass production is an assembly process that produces a large

number of identical products. It usually involves an assembly line in which em-

ployees at each workstation continuously perform the same task to assemble the

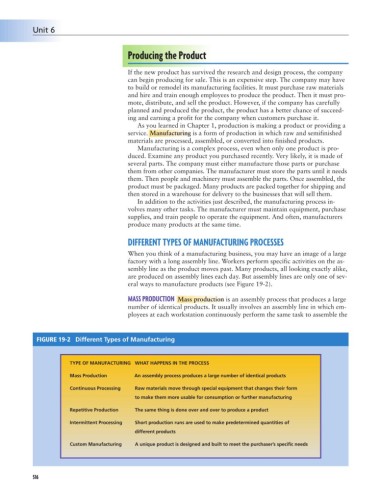

FIGURE 19-2 Different Types of Manufacturing

TYPE OF MANUFACTURING WHAT HAPPENS IN THE PROCESS

Mass Production An assembly process produces a large number of identical products

Continuous Processing Raw materials move through special equipment that changes their form

to make them more usable for consumption or further manufacturing

Repetitive Production The same thing is done over and over to produce a product

Intermittent Processing Short production runs are used to make predetermined quantities of

different products

Custom Manufacturing A unique product is designed and built to meet the purchaser’s specific needs

516