Page 642 - Environment: The Science Behind the Stories

P. 642

and economic efficiency. Industrial ecologists would reshape recycled enough aluminum cans and white paper in five years

industry so that nearly everything produced in a manufacturing to save $205,000 and recycled 3000 broken baggage contain-

process is used, either within that process or in a different one. ers into lawn furniture. A program to gather suggestions from

The larger idea behind industrial ecology is that indus- employees brought over 700 ideas to reduce waste—and 15

trial systems should function more like ecological systems, of these ideas saved the company over $8 million.

in which organisms use almost everything that is produced. The Swiss Zero Emissions Research and Initiatives

This principle brings industry closer to the ideal of ecological (ZERI) Foundation sponsors dozens of innovative projects

economists, in which economies function in a circular fashion worldwide that attempt to create goods and services without

rather than a linear one (p. 168). generating waste. One example involves breweries in Canada,

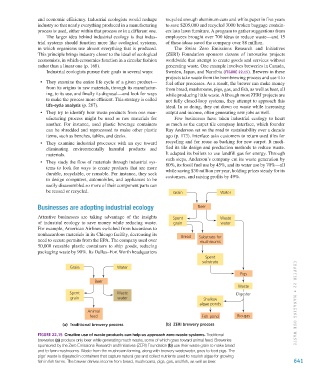

Industrial ecologists pursue their goals in several ways: Sweden, Japan, and Namibia (FIGURE 22.15). Brewers in these

projects take waste from the beer-brewing process and use it to

• They examine the entire life cycle of a given product— fuel other processes. As a result, the brewer can make money

from its origins in raw materials, through its manufactur- from bread, mushrooms, pigs, gas, and fish, as well as beer, all

ing, to its use, and finally its disposal—and look for ways while producing little waste. Although most ZERI projects are

to make the process more efficient. This strategy is called not fully closed-loop systems, they attempt to approach this

life-cycle analysis (p. 287). ideal. In so doing, they cut down on waste while increasing

• They try to identify how waste products from one man- output and income, often generating new jobs as well.

ufacturing process might be used as raw materials for Few businesses have taken industrial ecology to heart

another. For instance, used plastic beverage containers as much as the carpet tile company Interface, which founder

can be shredded and reprocessed to make other plastic Ray Anderson set on the road to sustainability over a decade

items, such as benches, tables, and decks. ago (p. 173). Interface asks customers to return used tiles for

• They examine industrial processes with an eye toward recycling and for reuse as backing for new carpet. It modi-

eliminating environmentally harmful products and fied its tile design and production methods to reduce waste.

materials. It adapted its boilers to use landfill gas for energy. Through

such steps, Anderson’s company cut its waste generation by

• They study the flow of materials through industrial sys- 80%, its fossil fuel use by 45%, and its water use by 70%—all

tems to look for ways to create products that are more while saving $30 million per year, holding prices steady for its

durable, recyclable, or reusable. For instance, they seek customers, and raising profits by 49%.

to design computers, automobiles, and appliances to be

easily disassembled so more of their component parts can

be reused or recycled. Grain Water Grain Water

Businesses are adopting industrial ecology Beer

Beer

Attentive businesses are taking advantage of the insights Spent Waste

Waste

Spent

of industrial ecology to save money while reducing waste. grain water

water

grain

For example, American Airlines switched from hazardous to

nonhazardous materials in its Chicago facility, decreasing its Bread Substrate for

Animal

need to secure permits from the EPA. The company used over mushrooms

feed

50,000 reusable plastic containers to ship goods, reducing

(a) Traditional brewery process

packaging waste by 90%. Its Dallas–Fort Worth headquarters

Spent

substrate

Grain Water Grain Water

Pigs

Beer Beer

Waste

Spent Waste Spent Waste Digester

grain water grain water

Shallow

algae ponds CHAPTER 22 • MAN A GING OUR WASTE

Animal Bread Substrate for

feed mushrooms Fish pond Bio-gas

(a) Traditional brewery process (b) ZERI brewery process

Spent

FIGURE 22.15 Creative use of waste products can help us approach zero-waste systems. Traditional

substrate

breweries (a) produce only beer while generating much waste, some of which goes toward animal feed. Breweries

sponsored by the Zero Emissions Research and Initiatives (ZERI) Foundation (b) use their waste grain to make bread

Pigs

and to farm mushrooms. Waste from the mushroom farming, along with brewery wastewater, goes to feed pigs. The

pigs’ waste is digested in containers that capture natural gas and collect nutrients used to nourish algae for growing

fish in fish farms. The brewer derives income from bread, mushrooms, pigs, gas, and fish, as well as beer. Waste 641

Digester

Shallow

algae ponds

Fish pond Bio-gas

M22_WITH7428_05_SE_C22.indd 641 13/12/14 2:25 PM

(b) ZERI brewery process