Page 15 - Stanochny park

P. 15

INNOVATIVE TECHNOLOGY INNOVATIVE TECHNOLOGY

drilling without filler, the vibration It can be argued that the presence of fillers filling the cavity of the work piece with

amplitudes in the frequency ranges where uniform adherence to the walls stabilizes the process of drilling parts from the HLPC, reduces

the natural frequencies of the tool are the intensity and amplitude of vibrations. In the feed range 0.2 ... 0.6 mm / rev, the likelihood

present sharply increase. When drilling of low-frequency vibrations and, accordingly, the probability of delamination is significantly

work pieces, the free space of which was reduced.

filled with a compound, the vibration

amplitudes are much lower at almost all SKZ, mV

frequencies (Fig. 7).

In general, the process of drilling

work pieces with free space (without

fillers) is characterized by bursts of

а vibrations with a large amplitude during

the transition from the glass-fiber layer of

the winding to the reinforcement package

and also from the package to the winding

layer. This is due to the mobility of the

HLPC layers during drilling in the absence

of filler. When filling the free space

with tight-fitting fillers, vibration bursts

occur less often, and their amplitude is

significant below.

b

Fig. 4. Placement of fillers in the free space of the work piece:

1 - reinforcement package; 2 - aluminum bar; 3 - compound.

Hz

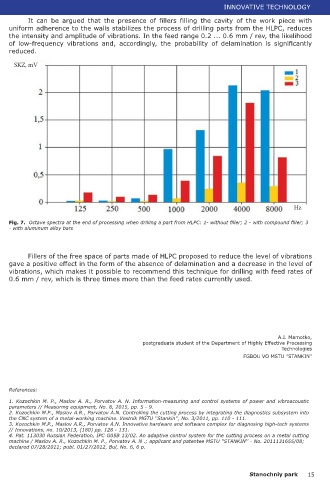

Fig. 7. Octave spectra at the end of processing when drilling a part from HLPC: 1- without filler; 2 - with compound filler; 3

Dimensions h of delamination, mm Fig. 5. Dependence of the gave a positive effect in the form of the absence of delamination and a decrease in the level of

- with aluminum alloy bars

Fillers of the free space of parts made of HLPC proposed to reduce the level of vibrations

vibrations, which makes it possible to recommend this technique for drilling with feed rates of

0.6 mm / rev, which is three times more than the feed rates currently used.

magnitude of the delamination

h in the reinforcement

package on the feed at a

constant drilling speed V =

30 m / min: 1 - without filler;

2 - with aluminum alloy bars;

Feed, mm / rev 3 - with compound..

A.I. Mamotko,

winding was determined as the difference postgraduate student of the Department of Highly Effective Processing

Technologies

between the nominal diameter of the FGBOU VO MSTU "STANKIN"

hole to be machined and the maximum

diameter of the circle into which the

delaminated pieces of fabric fit.

To register VA signals, we used

the equipment developed at MSTU 15 m/min References:

30 m/min

''STANKIN'' [1 - 3]. Received root-mean- delamination value Δ, mm 60 m/min 1. Kozochkin M. P., Maslov A. R., Porvatov A. N. Information-measuring and control systems of power and vibroacoustic

square values (RMS) of signal amplitudes parameters // Measuring equipment, No. 8, 2015, pp. 5 - 9.

and diagrams of octave spectra in time 2. Kozochkin M.P., Maslov A.R., Porvatov A.N. Controlling the cutting process by integrating the diagnostics subsystem into

intervals corresponding for each specific the CNC system of a metal-working machine. Vestnik MGTU ''Stankin'', No. 3/2011, pp. 110 - 111.

3. Kozochkin M.P., Maslov A.R., Porvatov A.N. Innovative hardware and software complex for diagnosing high-tech systems

drilling mode to the drill entry, the middle // Innovations, no. 10/2013, (180) pp. 128 - 131.

of the gain package and the drill exit. 4. Pat. 113030 Russian Federation, IPC G05B 13/02. An adaptive control system for the cutting process on a metal cutting

The analysis of the VA signal Feed, mm / rev machine / Maslov A. R., Kozochkin M. P., Porvatov A. N .; applicant and patentee MSTU ''STANKIN'' - No. 2011131655/08;

declared 07/28/2011; publ. 01/27/2012, Bul, No. 6, 6 p.

spectra during the drill exit from the

amplification package shows that when Fig. 6. Dependence of the delamination value Δ at the entrance to the

hole on the feed rate of a drill with a diameter of 10 mm

14 Stanochniy park Stanochniy park 15