Page 17 - Stanochny park

P. 17

INNOVATIVE TECHNOLOGY INNOVATIVE TECHNOLOGY

Experience in the

The experience of working

implementation of CAD / with machine-building enterprises

CAM / CAPP / PDM ADEM in shows that one of the most

demanded automation tools today

the end-to-end design and is a system that can be called ''shop

floor CAD''.

circle

The

production process from model of such products is very wide

consumers

of

to control program - from large industries with all

kinds of technological and design-

technological divisions, workshops and services to small manufacturers with the arsenal is only

a few machines.

The use of traditional automation tools, which have become widespread in design and

engineering departments, is not always suitable, or rather, it is almost always not suitable

for solving production problems. Here we need other opportunities and other software and

hardware solutions.

Fig. 1. The nominal model of the product. An example of successful implementation and

application of the ADEM system at the Moscow enterprise

MPO named after Rumyantsev can serve as such proof.

Below we will tell you step by step about the order of work

that took place at the enterprise, where, in addition to

the implementation of the system, the technology of

manufacturing the part was debugged and the post-

processor was refined for complex equipment.

A huge role in the process of preparing a model for

processing is played by the readiness of the

system, which is used by designers, to generate

export data. Experience shows that in this area

CAD systems can be divided into the following

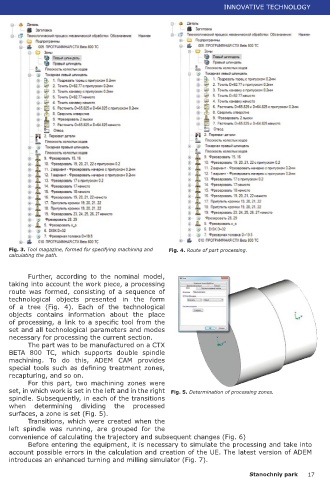

categories: Fig. 3. Tool magazine, formed for specifying machining and Fig. 4. Route of part processing.

calculating the path.

1. The system provides the means for

creating a direct data exchange interface.

This is the best option and allows for direct Further, according to the nominal model,

top-down integration. These products taking into account the work piece, a processing

include: Autodesk Inventor, Catia, ProE, route was formed, consisting of a sequence of

SolidWorks. ADEM implements a direct technological objects presented in the form

interface with them; of a tree (Fig. 4). Each of the technological

2. The system has developed export objects contains information about the place

through 3D exchange standards such as of processing, a link to a specific tool from the

SAT, IGES, STEP, and 2D exchange via DXF. set and all technological parameters and modes

With the mutual desire of the parties, always you necessary for processing the current section.

can establish competent data exchange without The part was to be manufactured on a CTX

Fig. 2. Formation of the losing geometric information. There are many BETA 800 TC, which supports double spindle

work piece.

practical examples of this. machining. To do this, ADEM CAM provides

As a nominal model, which had to be made special tools such as defining treatment zones,

on a turning-milling machine, a part (see Fig. 1) in STEP format and in the internal format of recapturing, and so on.

the SolidWorks system, which came from the designers, was presented. For this part, two machining zones were

It is known that the technologist in one way or another uses the means of the CAD system. set, in which work is set in the left and in the right Fig. 5. Determination of processing zones.

For example, for constructing technological surfaces, since the technological model differs from spindle. Subsequently, in each of the transitions

the nominal design one and sometimes very strongly. Thus, the ADEM CAD module was used to when determining dividing the processed

build a blank (see Fig. 2). surfaces, a zone is set (Fig. 5).

Since the set of tools was known, using the tools for forming the tool magazine, a set of Transitions, which were created when the

cutters and cutters were created that were used to process this part (Fig. 3). left spindle was running, are grouped for the

The part was to be manufactured on a CTX BETA 800 TC, which supports double spindle convenience of calculating the trajectory and subsequent changes (Fig. 6)

machining. To do this, the ADEM CAM module provides special tools such as defining treatment Before entering the equipment, it is necessary to simulate the processing and take into

zones, overriding, etc. account possible errors in the calculation and creation of the UE. The latest version of ADEM

introduces an enhanced turning and milling simulator (Fig. 7).

16 Stanochniy park Stanochniy park 17