Page 13 - Stanochny park

P. 13

INNOVATIVE TECHNOLOGY

Increasing the

WWX400 - INDEXABLE MILLING CUTTERS

Mitsubishi Materials has added a versatile indexable productivity of drilling

insert milling cutter to its extensive range of high of the helicopter

performance tools. The new WWX400 is a series of

true 90º corner milling cutters for face, shoulder and

copying applications. Featuring economical double- propellers made from

sided trigon inserts with 6 cutting edges, WWX400 has

been designed to meet all the needs of the modern high-strength laminated

metal cutting industry. polymer composites

Precision and reliability

The innovative and accurate geometry of the insert High-strength laminated polymer

pocket, together with precise locating of the inserts composites (HLPC) reinforced with titanium

on the tool body, ensures that a true 90º wall can

be machined on components. In most cases, this are used in the design of the rotor blades

and tail rotor blades of helicopters. The butt parts of the blades, intended for attachment to

eliminates the need for secondary finishing operations,

thereby saving valuable production time and costs. the engine rotor, are made by spiral winding of glass-carbon hybrid fabric, which is a tape

WWX400 cutters can perform at high feed rates to consisting of alternating layers of 0.01 ... 0.15 mm thick carbon tow and glass rod. The layers

ensure usability and efficiency across a wide choice Furthermore, a high maximum depth of cut of up to are impregnated with an epoxy molten binder.

of applications. The body features four contact faces 8.2mm enables efficient shoulder milling capabilities. To increase the strength of the butt part

inside the insert pocket, plus the use of a large screw, In order to meet component surface finish expectations, of the blade, it is reinforced with multilayer

that provides high insert clamping strength and stability the bottom of all inserts feature a large radius geometry packages consisting of titanium foil 0.1 mm

without compromising accuracy. This means it can be that acts like a traditional wiper. thick and a unidirectional fiberglass prepreg

used for semi-roughing as well finishing operations. (Fig. 1). The thickness of such a winding,

To further enhance usability and dependability, each Three different chipbreakers are available, the L, M which has a D-shaped section, is 50 mm, the

body has internal through coolant channels that exit and R breakers for light, medium and rough machining width of the free space a is 20 mm. In the

to supply high pressure cutting fluid directly at each respectively. These can be matched with an extensive parts from the HLPC obtained in this way,

insert. selection of 8 different coated and uncoated carbide the holes necessary for fixing the blades are

grades, providing choices that ensure the ideal processed. Typical defects when drilling holes

Innovative and economical inserts combination can be chosen to effectively machine a in parts made of HLPC are delamination of

The unique carbide inserts feature 6 usable cutting wide range of materials. the outer winding from fabric at the inlet and

edges that offer lower costs and excellent process outlet of the drill (Fig. 2) and delamination

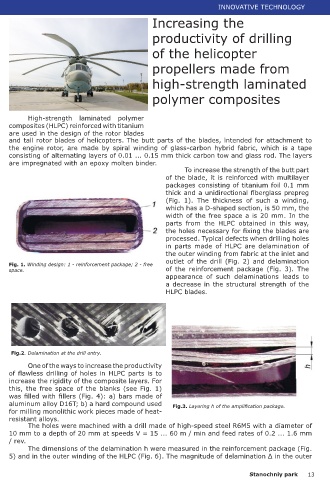

reliability thanks to a negative seating geometry but Sizes Fig. 1. Winding design: 1 - reinforcement package; 2 - free of the reinforcement package (Fig. 3). The

space.

provide a positive sharp cutting action. This generates The WWX400 arbor type face mill cutters are available appearance of such delaminations leads to

low cutting forces and together with an increase in from Ø50 - Ø250 in coarse, fine and extra fine pitch a decrease in the structural strength of the

insert thickness compared to conventional types, also geometries. Shank types from Ø50 - Ø80 can also be HLPC blades.

provides excellent resistance to breakage. specially ordered.

Fig.2. Delamination at the drill entry.

One of the ways to increase the productivity

of flawless drilling of holes in HLPC parts is to

increase the rigidity of the composite layers. For

this, the free space of the blanks (see Fig. 1)

was filled with fillers (Fig. 4): a) bars made of

90° WALL MACHINING aluminum alloy D16T; b) a hard compound used

UP TO 8.2 MM MULTIPLE INSERT for milling monolithic work pieces made of heat- Fig.3. Layering h of the amplification package.

DEPTH OF CUT CLAMPING FACES resistant alloys.

FOR ACCURACY AND

RELIABILITY The holes were machined with a drill made of high-speed steel R6M5 with a diameter of

LOW CUTTING FORCES 10 mm to a depth of 20 mm at speeds V = 15 ... 60 m / min and feed rates of 0.2 ... 1.6 mm

/ rev.

The dimensions of the delamination h were measured in the reinforcement package (Fig.

5) and in the outer winding of the HLPC (Fig. 6). The magnitude of delamination Δ in the outer

mmc-hardmetal.com

Stanochniy park 13