Page 80 - PPAP submission requirements (PPAP check sheet)

P. 80

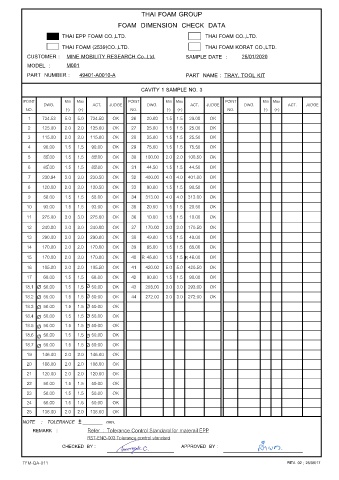

THAI FOAM GROUP

FOAM DIMENSION CHECK DATA

THAI EPP FOAM CO.,LTD. THAI FOAM CO.,LTD.

THAI FOAM (2539)CO.,LTD. THAI FOAM KORAT CO.,LTD.

CUSTOMER : MINE MOBILITY RESEARCH Co.,Ltd. SAMPLE DATE : 25/01/2020

MODEL : M001

PART NUMBER : 49401-A0010-A PART NAME : TRAY, TOOL KIT

CAVITY 1 SAMPLE NO. 3

POINT DWG. Min Max ACT. JUDGE POINT DWG. Min Max ACT. JUDGE POINT DWG. Min Max ACT. JUDGE

NO. (-) (+) NO. (-) (+) NO. (-) (+)

1 734.53 5.0 5.0 734.50 OK 26 20.00 1.5 1.5 20.00 OK

2 125.00 2.0 2.0 125.00 OK 27 25.00 1.5 1.5 25.00 OK

3 115.00 2.0 2.0 115.00 OK 28 25.00 1.5 1.5 25.50 OK

4 90.00 1.5 1.5 90.00 OK 29 75.00 1.5 1.5 75.50 OK

5 85.00 1.5 1.5 85.00 OK 30 100.00 2.0 2.0 100.50 OK

̊

̊

̊

6 85.00 1.5 1.5 85.00 OK 31 44.50 1.5 1.5 44.50 OK

̊

7 230.94 3.0 3.0 230.50 OK 32 400.00 4.0 4.0 401.00 OK

8 120.00 2.0 2.0 120.50 OK 33 90.00 1.5 1.5 90.50 OK

9 58.00 1.5 1.5 58.00 OK 34 313.00 4.0 4.0 313.00 OK

10 93.00 1.5 1.5 93.00 OK 35 20.00 1.5 1.5 20.50 OK

11 275.00 3.0 3.0 275.00 OK 36 10.00 1.5 1.5 10.00 OK

12 240.00 3.0 3.0 240.00 OK 37 170.00 2.0 2.0 170.50 OK

13 290.00 3.0 3.0 290.00 OK 38 49.00 1.5 1.5 49.00 OK

14 170.00 2.0 2.0 170.00 OK 39 65.00 1.5 1.5 65.00 OK

15 170.00 2.0 2.0 170.00 OK 40 R 46.00 1.5 1.5 46.00 OK

R

16 105.00 2.0 2.0 105.50 OK 41 420.00 5.0 5.0 420.50 OK

17 68.00 1.5 1.5 68.00 OK 42 90.00 1.5 1.5 90.00 OK

18.1 Ø 50.00 1.5 1.5 Ø 50.00 OK 43 293.00 3.0 3.0 293.00 OK

18.2 Ø 50.00 1.5 1.5 Ø 50.00 OK 44 272.00 3.0 3.0 272.00 OK

18.3 Ø 50.00 1.5 1.5 Ø 50.00 OK

18.4 Ø 50.00 1.5 1.5 Ø 50.00 OK

18.5 Ø 50.00 1.5 1.5 Ø 50.00 OK

18.6 Ø 50.00 1.5 1.5 Ø 50.00 OK

18.7 Ø 50.00 1.5 1.5 Ø 50.00 OK

19 146.00 2.0 2.0 146.00 OK

20 186.00 2.0 2.0 186.00 OK

21 120.00 2.0 2.0 120.00 OK

22 50.00 1.5 1.5 50.00 OK

23 50.00 1.5 1.5 50.00 OK

24 50.00 1.5 1.5 50.00 OK

25 138.00 2.0 2.0 138.00 OK

NOTE : TOLERANCE ± ________ mm.

REMARK : Refer : Tolerance Control Standard for materail EPP

RST-ENG-003 Tolerance control standard

CHECKED BY : APPROVED BY :

TFM-QA-011 REV. 02 ; 25/09/17