Page 75 - PPAP submission requirements (PPAP check sheet)

P. 75

Form 10.2.2

MOTHER PLANT MINE MODEL_______M001____________ INSPECTION STANDARD DATE 28/1/2020 PAGE 5 OF 6

PRE-CHECK PART NO. PART NAME FINISHED

DATE / / UNFINISHED

49404-A0010-A TRAY-TOOL-KIT

CASTING FORGING

ROUTE SUPPLIER MATERIAL GENERAL TOL. WEIGHT

THAI EPP FOAM CO., LTD. 295 ± 29.5 g

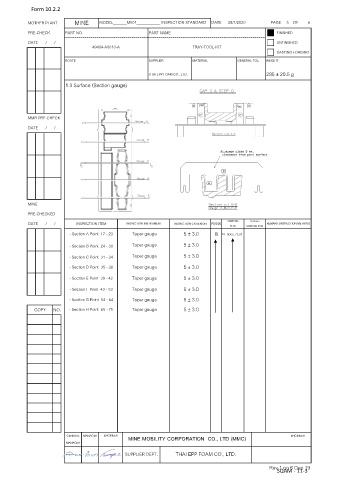

1.3 Surface (Section gauge)

MMR PRE-CHECK

DATE / /

MINE

PRE-CHECKED

DATE / / INSPECTION ITEM INSPECTION INSTRUMENT INSPECTION CRITERION RANK SAMPLING Customer REMARK (INSPECTION METHOD)

PLAN SAMPLING PLAN

- Section A Point 17 - 23 Taper gauge 5 ± 3.0 B N=3pcs. / Lot

- Section B Point 24 - 30 Taper gauge 5 ± 3.0

- Section C Point 31 - 34 Taper gauge 5 ± 3.0

- Section D Point 35 - 38 Taper gauge 5 ± 3.0

- Section E Point 39 - 42 Taper gauge 5 ± 3.0

- Section F Point 43 - 53 Taper gauge 5 ± 3.0

- Section G Point 54 - 64 Taper gauge 5 ± 3.0

COPY NO. - Section H Point 65 - 75 Taper gauge 5 ± 3.0

GENERAL MANAGER ENGINEER MINE MOBILITY CORPORATION CO., LTD (MMC) ENGINEER

MANAGER

SUPPLIER DEPT. THAI EPP FOAM CO., LTD.

Rev.1 on 6 Dec 19

SQAM - 11-3