Page 22 - Abraham Lincoln Hearse Narrative

P. 22

THIRD PROGRESS UPDATE ~ NOVEMBER, 2014 ~ ERIC HOLLENBECK

As anyone who’s been in the military will tell you, it is important to keep track of

the morale of the troops. Well, let me say, the last couple of weeks it wasn’t hard to see that

morale was headed downward. As well trained

and tenacious as these guys and gals are, “Parts

Is Parts!”, and that’s all we have been making for

the last nine weeks! It was definitely time to start

on the hearse body so one and all could see where

the parts go and that there actually was a reason

for making them.

We started with the framework of the floor

which was all mortise and tenon together, same

as the original would have been. We then went

to the framing.

Because of the

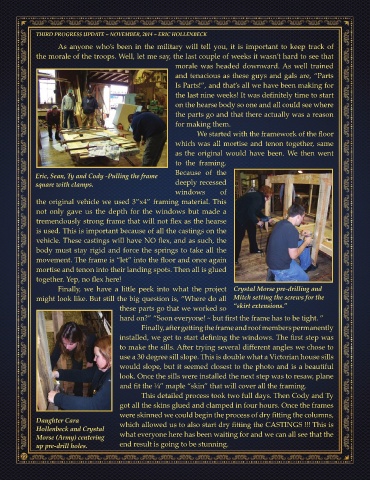

Eric, Sean, Ty and Cody -Pulling the frame

square with clamps. deeply recessed

windows of

the original vehicle we used 3”x4” framing material. This

not only gave us the depth for the windows but made a

tremendously strong frame that will not flex as the hearse

is used. This is important because of all the castings on the

vehicle. These castings will have NO flex, and as such, the

body must stay rigid and force the springs to take all the

movement. The frame is “let” into the floor and once again

mortise and tenon into their landing spots. Then all is glued

together. Yep, no flex here!

Finally, we have a little peek into what the project Crystal Morse pre-drilling and

might look like. But still the big question is, “Where do all Mitch setting the screws for the

these parts go that we worked so “skirt extensions.”

hard on?” “Soon everyone! ~ but first the frame has to be tight. ”

Finally, after getting the frame and roof members permanently

installed, we get to start defining the windows. The first step was

to make the sills. After trying several different angles we chose to

use a 30 degree sill slope. This is double what a Victorian house sills

would slope, but it seemed closest to the photo and is a beautiful

look. Once the sills were installed the next step was to resaw, plane

and fit the ¼” maple “skin” that will cover all the framing.

This detailed process took two full days. Then Cody and Ty

got all the skins glued and clamped in four hours. Once the frames

were skinned we could begin the process of dry fitting the columns,

Daughter Cara which allowed us to also start dry fitting the CASTINGS !!! This is

Hollenbeck and Crystal

Morse (Army) centering what everyone here has been waiting for and we can all see that the

up pre-drill holes. end result is going to be stunning.

22