Page 18 - Abraham Lincoln Hearse Narrative

P. 18

FIRST PROGRESS UPDATE ~ AUGUST, 2014 ~ ERIC HOLLENBECK

Hi All

I am proud to report that The Blue Ox Mill Veterans program project is underway.

Monday will be the start of our 5th week and already these boys have done more different

things than they ever would have imagined.

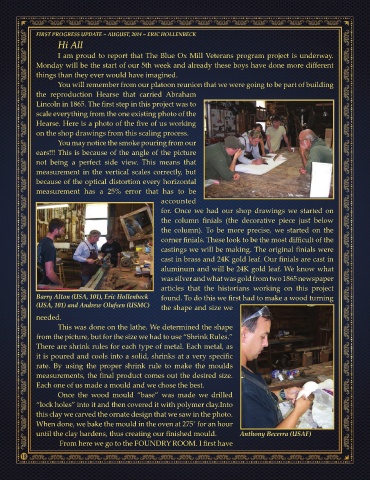

You will remember from our platoon reunion that we were going to be part of building

the reproduction Hearse that carried Abraham

Lincoln in 1865. The first step in this project was to

scale everything from the one existing photo of the

Hearse. Here is a photo of the five of us working

on the shop drawings from this scaling process.

You may notice the smoke pouring from our

ears!!! This is because of the angle of the picture

not being a perfect side view. This means that

measurement in the vertical scales correctly, but

because of the optical distortion every horizontal

measurement has a 25% error that has to be

accounted

for. Once we had our shop drawings we started on

the column finials (the decorative piece just below

the column). To be more precise, we started on the

corner finials. These look to be the most difficult of the

castings we will be making. The original finials were

cast in brass and 24K gold leaf. Our finials are cast in

aluminum and will be 24K gold leaf. We know what

was silver and what was gold from two 1865 newspaper

articles that the historians working on this project

Barry Alton (USA, 101), Eric Hollenbeck found. To do this we first had to make a wood turning

(USA, 101) and Andrew Olufsen (USMC) the shape and size we

needed.

This was done on the lathe. We determined the shape

from the picture, but for the size we had to use “Shrink Rules.”

There are shrink rules for each type of metal. Each metal, as

it is poured and cools into a solid, shrinks at a very specific

rate. By using the proper shrink rule to make the moulds

measurements, the final product comes out the desired size.

Each one of us made a mould and we chose the best.

Once the wood mould “base” was made we drilled

“lock holes” into it and then covered it with polymer clay.Into

this clay we carved the ornate design that we saw in the photo.

When done, we bake the mould in the oven at 275� for an hour

until the clay hardens, thus creating our finished mould. Anthony Becerra (USAF)

From here we go to the FOUNDRY ROOM. I first have

18