Page 27 - Stanochny park

P. 27

WELDING TECHNOLOGIES

AND EQUIPMENT

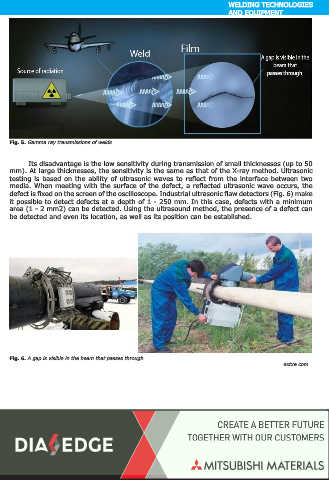

Fig. 5. Gamma ray transmissions of welds

Its disadvantage is the low sensitivity during transmission of small thicknesses (up to 50

mm). At large thicknesses, the sensitivity is the same as that of the X-ray method. Ultrasonic

testing is based on the ability of ultrasonic waves to reflect from the interface between two

media. When meeting with the surface of the defect, a reflected ultrasonic wave occurs, the

defect is fixed on the screen of the oscilloscope. Industrial ultrasonic flaw detectors (Fig. 6) make

it possible to detect defects at a depth of 1 - 250 mm. In this case, defects with a minimum

area (1 - 2 mm2) can be detected. Using the ultrasound method, the presence of a defect can

be detected and even its location, as well as its position can be established.

Fig. 6. A gap is visible in the beam that passes through

extxe.com

CREATE A BETTER FUTURE

TOGETHER WITH OUR CUSTOMERS