Page 28 - 22 Cotton SA magazine

P. 28

/ KWALITEITSBEHEER EN STANDAARDE

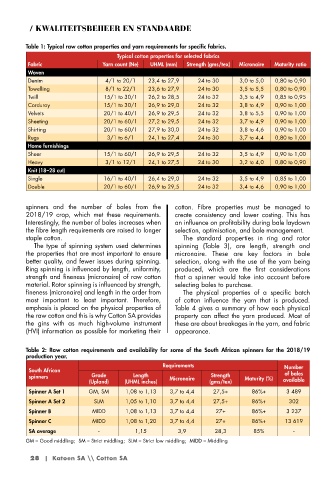

Table 1: Typical raw cotton properties and yarn requirements for specific fabrics.

Typical cotton properties for selected fabrics

Fabric Yarn count (Ne) UHML (mm) Strength (gms/tex) Micronaire Maturity ratio

Woven

Denim 4/1 to 20/1 23,4 to 27,9 24 to 30 3,0 to 5,0 0,80 to 0,90

Towelling 8/1 to 22/1 23,6 to 27,9 24 to 30 3,5 to 5,5 0,80 to 0,90

Twill 15/1 to 30/1 26,2 to 28,5 24 to 32 3,5 to 4,9 0,85 to 0,95

Corduroy 15/1 to 30/1 26,9 to 29,0 24 to 32 3,8 to 4,9 0,90 to 1,00

Velvets 20/1 to 40/1 26,9 to 29,5 24 to 32 3,8 to 5,5 0,90 to 1,00

Sheeting 20/1 to 60/1 27,2 to 29,5 24 to 32 3,7 to 4,9 0,90 to 1,00

Shirting 20/1 to 60/1 27,9 to 30,0 24 to 32 3,8 to 4,6 0,90 to 1,00

Rugs 3/1 to 6/1 24,1 to 27,4 24 to 30 3,7 to 4,4 0,80 to 1,00

Home furnishings

Sheer 15/1 to 60/1 26,9 to 29,5 24 to 32 3,5 to 4,9 0,90 to 1,00

Heavy 3/1 to 12/1 24,1 to 27,5 24 to 30 3,2 to 4,0 0,80 to 0,90

Knit (18–28 cut)

Single 16/1 to 40/1 26,4 to 29,0 24 to 32 3,5 to 4,9 0,85 to 1,00

Double 20/1 to 60/1 26,9 to 29,5 24 to 32 3,4 to 4,6 0,90 to 1,00

spinners and the number of bales from the cotton. Fibre properties must be managed to

2018/19 crop, which met these requirements. create consistency and lower costing. This has

Interestingly, the number of bales increases when an influence on profitability during bale laydown

the fibre length requirements are raised to longer selection, optimisation, and bale management.

staple cotton. The standard properties in ring and rotor

The type of spinning system used determines spinning (Table 3), are length, strength and

the properties that are most important to ensure micro naire. These are key factors in bale

better quality, and fewer issues during spinning. selection, along with the use of the yarn being

Ring spinning is influenced by length, uniformity, produced, which are the first considerations

strength and fineness (micronaire) of raw cotton that a spinner would take into account before

material. Rotor spinning is influenced by strength, selecting bales to purchase.

fineness (micronaire) and length in the order from The physical properties of a specific batch

most important to least important. Therefore, of cotton influence the yarn that is produced.

emphasis is placed on the physical properties of Table 4 gives a summary of how each physical

the raw cotton and this is why Cotton SA provides property can affect the yarn produced. Most of

the gins with as much high-volume instrument these are about breakages in the yarn, and fabric

(HVI) information as possible for marketing their appearance.

Table 2: Raw cotton requirements and availability for some of the South African spinners for the 2018/19

production year.

Requirements Number

South African of bales

spinners Grade Length Micronaire Strength Maturity (%)

(Upland) (UHML inches) (gms/tex) available

Spinner A Set 1 GM, SM 1,08 to 1,13 3,7 to 4,4 27,5+ 86%+ 3 489

Spinner A Set 2 SLM 1,05 to 1,10 3,7 to 4,4 27,5+ 86%+ 302

Spinner B MIDD 1,08 to 1,13 3,7 to 4,4 27+ 86%+ 3 237

Spinner C MIDD 1,08 to 1,20 3,7 to 4,4 27+ 86%+ 13 619

SA average - 1,15 3,9 28,3 85% -

GM – Good middling; SM – Strict middling; SLM – Strict low middling; MIDD – Middling

28 | Katoen SA \\ Cotton SA