Page 109 - UL_Report On_Part 1

P. 109

97 IITGN-UL/Façade 98 IITGN-UL/Façade

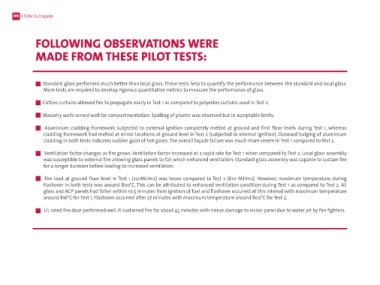

FOLLOWING OBSERVATIONS WERE

MADE FROM THESE PILOT TESTS:

• Standard glass performed much better than local glass. These tests help to quantify the performance between the standard and local glass.

More tests are required to develop rigorous quantitative metrics to measure the performance of glass.

• Cotton curtains allowed fire to propagate easily in Test 1 as compared to polyester curtains used in Test 2.

• Masonry walls served well for compartmentation. Spalling of plaster was observed but in acceptable limits.

• Aluminium cladding framework subjected to external ignition completely melted at ground and first floor levels during Test 1, whereas

cladding framework had melted at minor locations at ground level in Test 2 (subjected to internal ignition). Outward bulging of aluminium

cladding in both tests indicates sudden gush of hot gases. The overall façade failure was much more severe in Test 1 compared to Test 2.

• Ventilation factor changes as fire grows. Ventilation factor increased at a rapid rate for Test 1 when compared to Test 2. Local glass assembly

was susceptible to external fire allowing glass panels to fall which enhanced ventilation. Standard glass assembly was capable to sustain fire

for a longer duration before leading to increased ventilation.

2. Comparison of the two Glass+ACP tests: Tests 1 and 2 • Fire load at ground floor level in Test 1 (201MJ/m2) was lesser compared to Test 2 (610 MJ/m2). However, maximum temperature during

flashover in both tests was around 800°C. This can be attributed to enhanced ventilation condition during Test 1 as compared to Test 2. All

Test 1 was carried out to assess the performance of local glass and ACP glass and ACP panels had fallen within 10.5 minutes from ignition of fuel and flashover occurred at this interval with maximum temperature

assembly under fire whereas Test 2 assessed the performance of standard around 816°C for Test 1. Flashover occurred after 27 minutes with maximum temperature around 800°C for Test 2.

glass and ACP assembly. In both tests, 4mm thick ACP panels were used

along with glass assembly. ACP panel comprised of two aluminium sheets • UL rated fire door performed well. It sustained fire for about 45 minutes with minor damage to vision panel due to water jet by fire fighters.

with a polyethylene core sandwiched between them.

Test 1 used locally available toughened glass whereas Test 2 utilized Saint

Gobain reflective toughened glass. Both tests used glass panels of

1200mm x 400mm size with 6mm thickness. Test 1 considered fire from

external ignition source (wooden crib placed outside near façade

assembly) while Test 2 utilized an internal ignition source. Tests were

terminated as soon as fire reaches roof of second floor level.