Page 111 - UL_Report On_Part 1

P. 111

99 IITGN-UL/Façade 100 IITGN-UL/Façade

FOLLOWING OBSERVATIONS WERE

MADE FROM THESE PILOT TESTS:

• MDF responded better to fire than ACP. ACP sheets comprised of polyethylene core which is highly susceptible to fire. This stresses the need

to rethink about insulating polymer of ACP.

• It was observed that the glass panels did not break due to fire but fell to ground in intact form due to failure of pressure tapes and binder gel

(silicone structural sealant) used for fixing panel to the aluminium framework. Therefore, façade sealant plays an important role in enhancing

performance of façade assembly.

• Expansion of cladding framework also contributed to failure of glass panels in intact form. Major failure at the connections of the framework

members was observed. Horizontal and vertical aluminium member connections of cladding framework require special attention.

Image 45: View of Standard glass + ACP Image 46: View of Local glass + ACP

assembly after fire test (Test 1) assembly after fire test (Test 2)

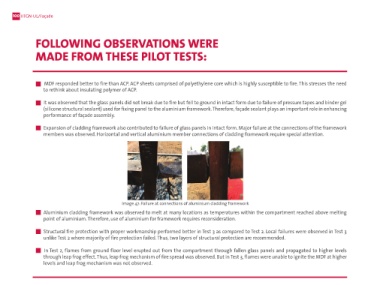

Image 47: Failure at connections of aluminium cladding framework

Image 45 and Image 46 confirm the higher susceptibility of local glass and ACP

assembly under fire. All glass panels and ACP sheets had fallen. Exposed and charred • Aluminium cladding framework was observed to melt at many locations as temperatures within the compartment reached above melting

polyethylene core can be viewed in Image 45 point of aluminium. Therefore, use of aluminium for framework requires reconsideration.

ACP boards allowed inner insulation polymer to be exposed to fire and subsequently • Structural fire protection with proper workmanship performed better in Test 3 as compared to Test 2. Local failures were observed in Test 3

initiate small secondary fire at ground level. Polyethylene core sandwiched between unlike Test 2 where majority of fire protection failed. Thus, two layers of structural protection are recommended.

two aluminium sheets was exposed to fire and charred in both tests. Insulation filling

of ACP is a major concern. • In Test 2, flames from ground floor level erupted out from the compartment through fallen glass panels and propagated to higher levels

through leap frog effect. Thus, leap frog mechanism of fire spread was observed. But in Test 3, flames were unable to ignite the MDF at higher

levels and leap frog mechanism was not observed.