Page 113 - UL_Report On_Part 1

P. 113

101 IITGN-UL/Façade 102 IITGN-UL/Façade

MAJOR OBSERVATIONS OF GLASS BEHAVIOR

4. Comparison of Internal v/s External fire spread

Fire tests 1, 2 and 3 were performed by igniting the fuel source and fire was allowed to grow naturally breaking the façade assembly and FROM THESE PILOT TESTS ARE AS FOLLOWS:

propagating to higher floor levels through leap frog effect. Test 4 was carried out involving internal fire spread mechanism. The aim was to study

the performance of normal fire stop material provided in form of plywood planks between façade framework and slab.

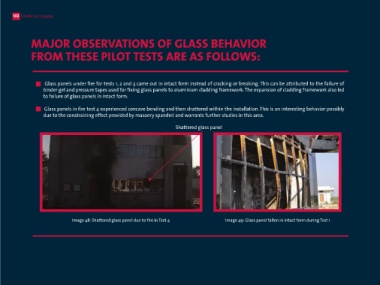

FOLLOWING OBSERVATIONS ARE • Glass panels under fire for tests 1, 2 and 3 came out in intact form instead of cracking or breaking. This can be attributed to the failure of

binder gel and pressure tapes used for fixing glass panels to aluminium cladding framework. The expansion of cladding framework also led

MADE THROUGH THESE TESTS: to failure of glass panels in intact form.

• Glass panels in fire test 4 experienced concave bending and then shattered within the installation. This is an interesting behavior possibly

due to the constraining effect provided by masonry spandrel and warrants further studies in this area.

• Fire stop provided in form of plywood planks undergoes early failure and leads to rapid internal propagation of fire. Fire propagated to first Shattered glass panel

and second floor levels within 10 minutes and 11.5 minutes, respectively, from time of ignition of fuel at ground floor level.

• 1.5 hour UL rated glass wool provided as fire stop material for tests 1, 2 and 3 performed well and did not led to internal fire spread mechanism.

• Selection of proper rated fire stop material is crucial. Proper workmanship during its installation is important to fulfill the purpose.

5. Glass behavior

Glass panels in combination with other associated cladding material used in façade assemblies were tested under fire. Tests 1, 2 and 3 were

subjected to external fire spread mechanism whereas test 4 was subjected to internal fire spread. Glass panels of size 1200mm x 400mm and

thickness 6mm were used for all tests.

Image 48: Shattered glass panel due to fire in Test 4 Image 49: Glass panel fallen in intact form during Test 1