Page 15 - Graypvine December 2020

P. 15

customer what they needed, WHEN they needed In summary, the customer is extremely impressed

it. Gray awarded the steel contracts on this project with Gray’s innovative ways of thinking. They are so

to Prospect Steel for fabrication and to Building impressed that they have asked other developers and

Zone Industries (BZI) for the erection. BZI is known general contractors to come visit Project Diamond

nationally for their ability to panelize steel and deck. to see how Gray does it! We are looking forward to

With this building being a 5-story structure, BZI’s another great year with Amazon. With Gray being a

panelization resume was a large reason the team valued builder in this program, we expect a lot more

locked them in as a partner. Along with this article, opportunity in the coming years and plan to perform

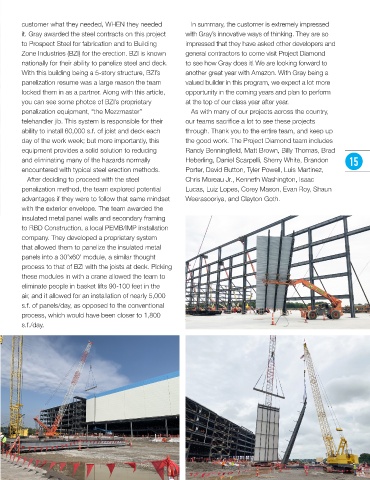

you can see some photos of BZI’s proprietary at the top of our class year after year.

penalization equipment, “the Mezzmaster” As with many of our projects across the country,

telehandler jib. This system is responsible for their our teams sacrifice a lot to see these projects

ability to install 60,000 s.f. of joist and deck each through. Thank you to the entire team, and keep up

day of the work week; but more importantly, this the good work. The Project Diamond team includes

equipment provides a solid solution to reducing Randy Benningfield, Matt Brown, Billy Thomas, Brad

and eliminating many of the hazards normally Heberling, Daniel Scarpelli, Sherry White, Brandon 15

encountered with typical steel erection methods. Porter, David Button, Tyler Powell, Luis Martinez,

After deciding to proceed with the steel Chris Moreau Jr., Kenneth Washington, Isaac

penalization method, the team explored potential Lucas, Luiz Lopes, Corey Mason, Evan Roy, Shaun

advantages if they were to follow that same mindset Weerasooriya, and Clayton Goth.

with the exterior envelope. The team awarded the

insulated metal panel walls and secondary framing

to RBD Construction, a local PEMB/IMP installation

company. They developed a proprietary system

that allowed them to panelize the insulated metal

panels into a 30’x60’ module, a similar thought

process to that of BZI with the joists at deck. Picking

these modules in with a crane allowed the team to

eliminate people in basket lifts 90-100 feet in the

air, and it allowed for an installation of nearly 5,000

s.f. of panels/day, as opposed to the conventional

process, which would have been closer to 1,800

s.f./day.