Page 22 - UK Standard Products Catalogue 2018_23.10.18

P. 22

Material Specifications Aluminium

Aluminium.

Our poles are produced from 6060T5 Aluminium alloy, the

brackets and other tubular elements from 6060T6 alloy, the

backing plates from 5038H111, the resistance elements

from AlSi7Mg or AlSi10Mg cast Aluminium and decorative

parts in AlSi13 cast Aluminium.

These Aluminium alloys comply with NF EN 755 series

standards for conical posts, brackets and other tubular parts

as well as backing plates, and standard NF EN 1706 for

parts in cast Aluminium.

Bars, tubes and spun profiles - 6060T5 or T6:

The mechanical characteristics are obtained by tempering and rendering. Valmont’s specific rendering treatment makes it

possible to obtain above-standard mechanical characteristics.

The 6060 alloy is a good compromise between mechanical strength and corrosion; it is particularly apt for anodising and cold

deforming. Good welding results are obtained with classic procedures under inert gas (TIG or MIG).

Piece of cast Aluminium AlSi7Mg and AlSi10Mg:

There are two main casting processes used - sand or shell - according to the geometrical complexity of the product, the

degree of precision needed for the dimensions and the quantities to be produced.

According to the level of resistance required, the pieces can be heat treated.

Constraint

TS

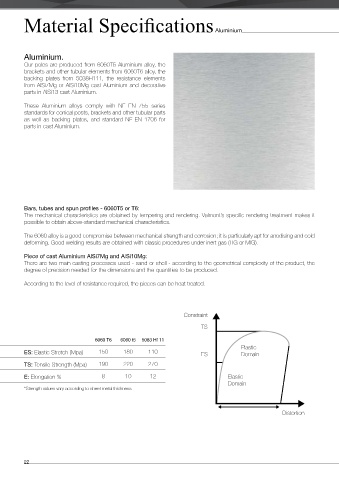

6060 T6 6060 t5 5083 H111

Plastic

ES: Elastic Stretch (Mpa) 150 180 110 ES Domain

TS: Tensile Strength (Mpa) 190 220 270

E: Elongation % 8 10 12 Elastic

Domain

*Strength values vary according to sheet metal thickness.

Distortion

22