Page 26 - UK Standard Products Catalogue 2018_23.10.18

P. 26

Material Specifications Stainless and Corten

Stainless Steel.

Our columns and brackets are produced from Grade 304L &

316L austenitic stainless steel , these types of steel conform

with following standards:

EN10088-2:– Stainless Steel.

1.4301 - XBS1449 – Grade 304L

1.4401 - XBS1449 – Grade 316L

Corrosion Resistance.

The corrosion resistance of stainless steel is attributed to the thin passive film that forms spontaneously on its surface in

oxidizing environments if the steel has a minimum chromium content of approximately 10.5%.(Which both Gr304L and 316L do).

As the film adheres strongly to the metal substrate and protects it from contact with the surrounding environment, the

electrochemical reactions that cause corrosion are effectively stopped. If locally destroyed, for example by scratching, the

film can ‘heal’ by spontaneously re-passivating in an oxidizing environment.

Finishing.

As for the finishing of our stainless steel products, Due to largely being used as roadside structures we opt for a process of

stainless steel bead abrading, to create a homogenous automated satin finish, which can be sealed with a clear coating on

request. Both mirror finishing and electroplating are available for decorative stainless structures, although are not advised for

roadside due to glare issues.

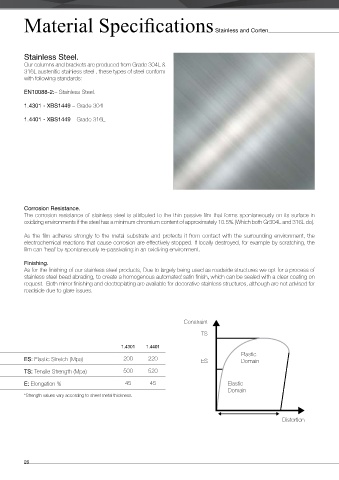

Constraint

TS

1.4301 1.4401

Plastic

ES: Elastic Stretch (Mpa) 200 220 ES Domain

TS: Tensile Strength (Mpa) 500 520

E: Elongation % 45 45 Elastic

Domain

*Strength values vary according to sheet metal thickness.

Distortion

26