Page 187 - 2017 Lashing Catalog Web_Neat

P. 187

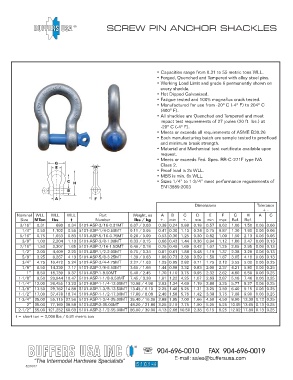

® SCREW PIN ANCHOR SHACKLES

• Capacities range from 0.31 to 55 metric tons WLL.

• Forged, Quenched and Tempered with alloy steel pins.

• Working Load Limit and grade 6 permanently shown on

every shackle.

• Hot Dipped Galvanized.

• Fatigue tested and 100% magnaflux crack tested.

• Manufactured for use from -20º C (-4º F) to 204º C

(400º F).

• All shackles are Quenched and Tempered and meet

impact test requirements of 27 joules (20 ft. lbs.) at

-20º C (-4º F).

• Meets or exceeds all requirements of ASME B30.26

• Each manufacturing batch are sample tested to proofload

and minimum break strength.

• Material and Mechanical test certificate available upon

request.

• Meets or exceeds Fed. Spec. RR-C-271F type IVA

G Class 2.

E D

• Proof load is 2x WLL.

• MBS is min. 6x WLL.

C H • Sizes 1/4” to 1-3/4” meet performance reguirements of

EN13889:2003

B

A F

Dimensions Tolerance

+ -

Nominal WLL WLL WLL Part Weight, ea A B C D E F G H A C

Size MTon lbs t Number lbs / kg +- min +- min min max Ref. Ref.

3/16” 0.31 680 0.34 5101-ASP-3/16-0.31MT 0.07 / 0.03 0.38 0.24 0.88 0.18 0.57 0.62 1.00 1.50 0.06 0.06

1/4” 0.50 1,102 0.55 5101-ASP-1/4-0.50MT 0.11 / 0.05 0.47 0.30 1.13 0.24 0.75 0.87 1.30 1.90 0.06 0.06

5/16” 0.75 1,653 0.83 5101-ASP-5/16-0.75MT 0.20 / 0.09 0.53 0.36 1.25 0.30 0.82 1.00 1.50 2.13 0.06 0.06

3/8” 1.00 2,204 1.10 5101-ASP-3/8-1.00MT 0.33 / 0.15 0.66 0.43 1.44 0.36 0.94 1.12 1.80 2.47 0.06 0.13

7/16” 1.50 3,307 1.65 5101-ASP-7/16-1.50MT 0.40 / 0.18 0.75 0.49 1.69 0.42 1.07 1.25 2.05 2.95 0.06 0.13

1/2” 2.00 4,409 2.20 5101-ASP-1/2-2.00MT 0.75 / 0.34 0.81 0.61 1.88 0.48 1.19 1.37 2.38 3.28 0.06 0.13

5/8” 3.25 8,267 4.13 5101-ASP-5/8-3.25MT 1.39 / 0.63 1.06 0.73 2.38 0.59 1.50 1.87 3.05 4.16 0.06 0.13

3/4” 4.75 10,472 5.24 5101-ASP-3/4-4.75MT 2.27 / 1.03 1.25 0.85 2.82 0.71 1.75 2.12 3.55 5.00 0.06 0.25

7/8” 6.50 14,330 7.17 5101-ASP-7/8-6.50MT 3.65 / 1.66 1.44 0.98 3.32 0.83 2.00 2.37 4.21 5.80 0.06 0.25

1” 8.50 18,739 9.37 5101-ASP-1-8.50MT 5.40 / 2.45 1.70 1.10 3.75 0.95 2.32 2.62 4.80 6.50 0.06 0.25

1-1/8” 9.50 20,944 10.47 5101-ASP-1-1/8-9.50MT 7.45 / 3.38 1.81 1.22 4.25 1.07 2.63 2.87 5.18 7.46 0.06 0.25

1-1/4” 12.00 26,455 13.23 5101-ASP-1-1/4-12.00MT 10.98 / 4.98 2.03 1.34 4.69 1.19 2.88 3.25 5.77 8.27 0.06 0.25

1-3/8” 13.50 29,762 14.88 5101-ASP-1-3/8-13.50MT 13.45 / 6.10 2.25 1.46 5.25 1.31 3.25 3.50 6.40 9.15 0.06 0.25

1-1/2” 17.00 37,478 18.74 5101-ASP-1-1/2-17.00MT 17.80 / 8.08 2.40 1.58 5.76 1.42 3.38 3.75 7.08 9.90 0.06 0.25

1-3/4” 25.00 55,115 27.56 5101-ASP-1-3/4-25.00MT 35.40 / 16.06 2.88 1.95 7.00 1.66 4.50 4.50 8.90 12.30 0.13 0.25

2” 35.00 77,160 38.58 5101-ASP-2-35.00MT 48.20 / 21.86 3.25 2.19 7.75 1.90 5.25 5.25 10.05 13.65 0.13 0.25

2-1/2” 55.00 121,252 60.63 5101-ASP-2-1/2-55.00MT 86.00 / 39.00 4.13 2.68 10.50 2.38 6.15 6.25 12.92 17.80 0.13 0.25

t = short ton = 2,000 lbs / 0.91 metric ton

®

904-696-0010 FAX 904-696-0019

E-mail: sales@buffersusa.com

5101-4

02/10/17