Page 34 - ST Sept

P. 34

INNOVATIVE TECHNOLOGY INNOVATIVE TECHNOLOGY

and is carried out according to a given technological program. An observation window is mounted Arc discharge

in the water-cooled chamber for visual observation of the process. It is important to note that most of the known plasma technologies are based on the use

of an arc discharge (electric arc) as an energy source for conducting technological processes.

Arc discharges are called discharges at a current density of 102 - 103 A / mm2 and a

relatively low cathode potential drop of the order of the ionization and excitation potentials of

the atoms of the gaseous medium or the evaporated metal. The small value of the cathodic

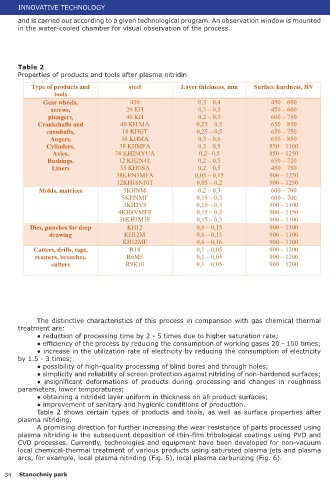

Table 2. potential drop is the result of the action of other mechanisms of cathodic electron emission than

Properties of products and tools after plasma nitridin in a glow discharge. They create a current density that allows the full discharge current to flow.

Type of products and steel Layer thickness, mm Surface hardness, HV

tools

Gear wheels, 450 0,3 – 0,4 450 – 600

screws, 20 KH 0,3 – 0,5 450 – 600

plungers, 40 KH 0,2 – 0,5 600 – 750

Crankshafts and 40 KH МА 0,25 – 0,5 650 – 850

camshafts, 18 KHGТ 0,25 – 0,5 650 – 750

Augers, 38 KHМА 0,3 – 0,6 650 – 850

Cylinders, 38 KHМFА 0,3 – 0,5 850 – 1100

Axles, 38 KH2МYUА 0,2– 0,5 850 – 1250

Bushings, 12 KH2N4L 0,2 – 0,5 650 – 720

Liners 35 KHGSА 0,2 – 0,5 450 – 750

38KHN3МFА 0,05 – 0,15 900 – 1250

12KH18N10Т 0,05 – 0,2 900 – 1250

Molds, matrices 5KHNМ 0,2 – 0,3 600 – 700 a b c

5KHNМF 0,15 – 0,3 600 – 700

3KH2V8 0,15 – 0,3 900 – 1100 Fig. 4. Plasma nitriding unit, working chamber diameter 350 mm, height 500 mm, power consumption 3 kW (a), type of

4KH4VМFS 0,15 – 0,3 900 – 1150 products in a glow discharge in the process plasma nitriding (b).

30KH3М3F 0,15 – 0,3 900 – 1100

Dies, punches for deep KH12 0,6 – 0,15 900 – 1100 Arc cathodes emit electrons as a result of thermionic, autoelectric and thermoautoelectronic

drawing KH12М 0,6 – 0,15 900 – 1100 emissions. Characteristic parameters of arc discharges: current 1 - 105 A, voltage from 20 - 30

KH12МF 0,6 – 0,16 900 – 1100 V (short arcs) to kilovolts.

Cutters, drills, taps, R18 0,1 – 0,05 900 – 1200 The main types of arc discharges that are widely used for technological purposes are: at

reamers, broaches, R6М5 0,1 – 0,05 900 – 1200 low pressure, a discharge with a cold cathode and moving cathode spots (emission occurs from

cutters R9К10 0,1 – 0,05 900 – 1200

constantly moving cathode spots with a current density of 104 - 107 A / cm2); at high pressure

(0.1 - 1.0 atm) - dense low-temperature equilibrium plasma with an electron temperature of

0.5 - 1.0 eV and higher.

Table 3.

The distinctive characteristics of this process in comparison with gas chemical thermal Characteristics of the installation for microplasma treatment.

treatment are:

● reduction of processing time by 2 - 5 times due to higher saturation rate;

● efficiency of the process by reducing the consumption of working gases 20 - 100 times; Power consumption, kW 0,5

● increase in the utilization rate of electricity by reducing the consumption of electricity Mains supply voltage, V 220

by 1.5 - 3 times; Limits of step current regulation, A 10 – 20

● possibility of high-quality processing of blind bores and through holes; Working voltage, no more V 14

● simplicity and reliability of screen protection against nitriding of non-hardened surfaces; Argon consumption, no more than l / min 1,5

● insignificant deformations of products during processing and changes in roughness

parameters, lower temperatures; Autonomous cooling system volume, l 4

● obtaining a nitrided layer uniform in thickness on all product surfaces; Overall dimensions of the microplasmatron, (diameter x length), (8 – 16) х (50 –

● improvement of sanitary and hygienic conditions of production. mm 250)

Table 2 shows certain types of products and tools, as well as surface properties after Overall dimensions, mm 500х450х250х

plasma nitriding. Installation weight, kg 25

A promising direction for further increasing the wear resistance of parts processed using

plasma nitriding is the subsequent deposition of thin-film tribological coatings using PVD and

CVD processes. Currently, technologies and equipment have been developed for non-vacuum

local chemical-thermal treatment of various products using saturated plasma jets and plasma

arcs, for example, local plasma nitriding (Fig. 5), local plasma carburizing (Fig. 6).

34 Stanochniy park Stanochniy park 35