Page 29 - ST Sept

P. 29

INNOVATIVE TECHNOLOGY INNOVATIVE TECHNOLOGY

HARD ALLOY COATING TECHNOLOGY At this stage, the following processes take place:

● recrystallization of tungsten carbide through the liquid phase;

● splicing of neighboring grains due to the predominant growth of one grain at the

The article discusses the production of wear-resistant composite expense of others;

coatings using electrocontact sintering of powders. It is shown

that electric contact sintering provides for electric heating of a steel

metal powder, poured between the part and the electrode, due to

the thermal energy released by the electric current at the active

A significant increase in the performance of many types resistance.

of products is achieved by applying coatings on their surfaces

based on a compound of tungsten and titanium. The use of

such coatings allows not only to increase the wear resistance

of products and tools several times, but also to design

fundamentally new types of tools and friction units.

Unlike other types and methods of applying coatings,

electrocontact sintering allows forming a working layer with a thickness of 0.5 ... 2.5 mm

directly in the process. Thus, the resulting coating is no longer an integral part of the surface

of the product, which improves its properties, but works as an independent body, taking on the

entire load.

Obtaining wear-resistant composite coatings by electrocontact sintering of powders is coating substrate

most competitive on tools, on the working

surfaces of which it is practically impossible

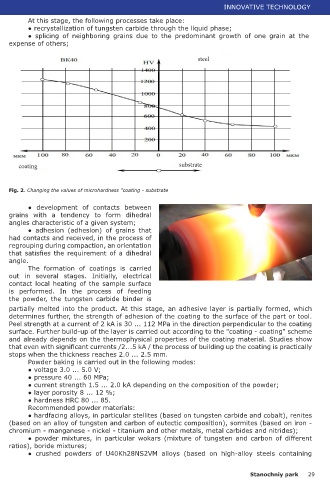

for technical reasons to solder cutting hard- Fig. 2. Changing the values of microhardness "coating - substrate

alloy plates using known technologies.

These products include complex-

profile tools, complex-profile working bodies ● development of contacts between

of various crushers and the entire series of grains with a tendency to form dihedral

disc cutting tools. However, it is necessary angles characteristic of a given system;

to fulfill a number of requirements, which ● adhesion (adhesion) of grains that

are as follows: had contacts and received, in the process of

● ensure the hardness of the coating regrouping during compaction, an orientation

is at least 82 ... 85 HRC, that satisfies the requirement of a dihedral

angle.

unit control ● ensure reliable adhesion of the The formation of coatings is carried

powder coating to the substrate surface,

● The size of the applied coating must out in several stages. Initially, electrical

satisfy the conditions of maximum wear contact local heating of the sample surface

resistance for the given operation. is performed. In the process of feeding

Fig. 1. Schematic diagram of a coating installation with In our case, a technology has been the powder, the tungsten carbide binder is

electrocontact method developed for applying a wear-resistant partially melted into the product. At this stage, an adhesive layer is partially formed, which

composite coating on an installation determines further, the strength of adhesion of the coating to the surface of the part or tool.

mounted based on a lathe, and it is shown in Fig. 1. Peel strength at a current of 2 kA is 30 ... 112 MPa in the direction perpendicular to the coating

Deep regulation of the power required to reach temperatures of the order of 1500-2000 surface. Further build-up of the layer is carried out according to the "coating - coating" scheme

°C is provided by thyristor voltage control on the primary winding of the power transformer. and already depends on the thermophysical properties of the coating material. Studies show

Experimental data show that the depth of the transitional diffusion layer reaches 0.1 ... 0.15 that even with significant currents /2...5 kA / the process of building up the coating is practically

mm, which indicates good adhesion of the coating to the substrate. The results are shown in stops when the thickness reaches 2.0 ... 2.5 mm.

Fig. 2. Powder baking is carried out in the following modes:

The developed technology refers to low-waste and resource-saving ones. It becomes ● voltage 3.0 ... 5.0 V;

possible, without the use of complex molds, to make hard-alloy heat-resistant coatings on ● pressure 40 ... 60 MPa;

complex-profile tools and working bodies of crushing plants. ● current strength 1.5 ... 2.0 kA depending on the composition of the powder;

Using this technology, a coating was carried out on the working bodies of crushers for ● layer porosity 8 ... 12 %;

crushing rocks and agricultural products. The test results were compared with the working ● hardness HRC 80 ... 85.

bodies made of hardened steels of the ShKh15, 65G type. Tests show that crusher life is 10 to Recommended powder materials:

12 times longer than traditional hardened steel materials. ● hardfacing alloys, in particular stellites (based on tungsten carbide and cobalt), renites

Coatings applied to circular cutting tools designed for cutting rocks, such as granite, (based on an alloy of tungsten and carbon of eutectic composition), sormites (based on iron -

marble and others, almost completely replace diamond tools, however, the cost of coated tools chromium - manganese - nickel - titanium and other metals, metal carbides and nitrides);

is 3-4 times lower than diamond ones. ● powder mixtures, in particular wokars (mixture of tungsten and carbon of different

In technologies of electrocontact sintering of tool carbide powders, compositions based on ratios), boride mixtures;

tungsten carbide and cobalt are mainly used. When an electric current is applied in the sintering ● crushed powders of U40Kh28NS2VM alloys (based on high-alloy steels containing

stage following the powder compaction, the final formation of the alloy structure occurs.

28 Stanochniy park Stanochniy park 29