Page 31 - ST Sept

P. 31

INNOVATIVE TECHNOLOGY INNOVATIVE TECHNOLOGY

titanium, chromium, molybdenum, nickel, etc.). Industrial resource-saving plasma technologies

Thermophysical analysis of the "sample - coating" system with the use of electrocontact

heating allows us to assume that, in contrast to, for example, the plasma method or welding,

the surface of the product heats up more than the coating material. Heat is generated mainly at The active use of modern resource-saving

the points of contact of tungsten carbide grains with the sample surface. For a reliable process technological processes, which include plasma

flow, in this case, a certain gap between the electrode and the work piece is required, which is technologies, is an urgent task.

provided by the almost rough surface of the roller. Thus, the initial effect of the introduction of Plasma technologies are such production

current into the system consists in a sharp, abrupt increase in the temperature of the surface technologies that use the effect of plasma (the fourth state of aggregation of matter) on various

layer of the part and simultaneous mechanical penetration of carbide particles tungsten. Analysis materials for the purpose of manufacturing, maintenance, repair and / or operation of products

of the diffusion zone shows that a pronounced texture is observed only from the side of the [1]. Plasma is understood as an ionized gas in which the concentrations of positive and negative

coating. No noticeable deformation zones were found on the sample surface, and, consequently, electric charges are practically the same.

the thermal regime makes it possible to form coating on ready-to-use complex-profile parts and It should be noted that in plasma processes, there may be no mechanical contact of the

tools without further additional machining. tool (solid, liquid or gaseous body) with the work piece, and the action is carried out only by

plasma, or there may be a joint action of a traditional tool with plasma.

The general principle of operation of equipment for plasma processing methods is the

direct conversion of electrical energy into energy of technological impact. This equipment can

provide the creation and operation of both a source of thermal energy and a source of charged

particles. In this case, a whole range of technological processes can be implemented: melting,

remelting, welding, cutting, surfacing, spraying, deposition, hardening, modification, heat

hardening, cleaning, activation, bactericidal treatment, recycling and disposal of waste, and

others.

The use of plasma in numerous technological processes is based on the following effects:

anode

cathode

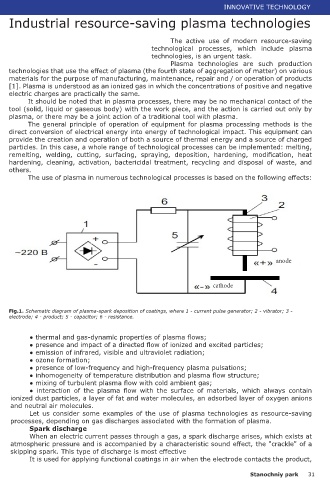

Fig.1. Schematic diagram of plasma-spark deposition of coatings, where 1 - current pulse generator; 2 - vibrator; 3 -

electrode; 4 - product; 5 - capacitor; 6 - resistance.

Sh.A. Karimov, E.O. Umarov, E. Khushvaktov.

Tashkent State Technical University. ● thermal and gas-dynamic properties of plasma flows;

. ● presence and impact of a directed flow of ionized and excited particles;

● emission of infrared, visible and ultraviolet radiation;

References: ● ozone formation;

1. Avseevich O.I. Regularities of erosion during pulsed discharges. Moscow, Mechanical Engineering, 1982. pp. 32 - 42. ● presence of low-frequency and high-frequency plasma pulsations;

2. Kisaev I.R. Cathodic processes of an electric arc. 1968, Moscow, Nauka, 244 p. ● inhomogeneity of temperature distribution and plasma flow structure;

3. Properties, production and scope of refractory compounds: reference ed. under. ed. Kosolapova T.Ya. M., metallurgy,

1986, 928 p. ● mixing of turbulent plasma flow with cold ambient gas;

4. Eremenko V.I., Naidich Yu.V., Lavrinenko I.A. Sintering in the presence of a liquid metal phase. Kiev, Naukova Dumka, ● interaction of the plasma flow with the surface of materials, which always contain

1963, 123 p. ionized dust particles, a layer of fat and water molecules, an adsorbed layer of oxygen anions

5. Kuzmenko P.P. Electrical transfer, thermal transfer and diffusion in metals. Kiev, High School, 1983. 151 p.

6. Skorokhodov V.V., Solonini S.M. Physical and metallurgical fundamentals of sintering and neutral air molecules.

powders. Moscow, metallurgy, 1984, 158 p. Let us consider some examples of the use of plasma technologies as resource-saving

7. Libenson G.A. Fundamentals of powder metallurgy. Moscow, Metallurgy, 1975. 200 p. processes, depending on gas discharges associated with the formation of plasma.

8. Raichenko A.I., Morozov A.S., Popov V.P. Powder metallurgy 1986, No. 2, pp. 41 - 44.

9. Hara Z., Akechi K., Itabashi M. J. Japan. Soc. Powder and Powder Met., 1975, V. 22, No. 3, pp. 101-106. Spark discharge

When an electric current passes through a gas, a spark discharge arises, which exists at

atmospheric pressure and is accompanied by a characteristic sound effect, the "crackle" of a

skipping spark. This type of discharge is most effective

It is used for applying functional coatings in air when the electrode contacts the product,

30 Stanochniy park Stanochniy park 31