Page 7 - 2018 Racecar Engineering Engine Parts and Accessories Catalog

P. 7

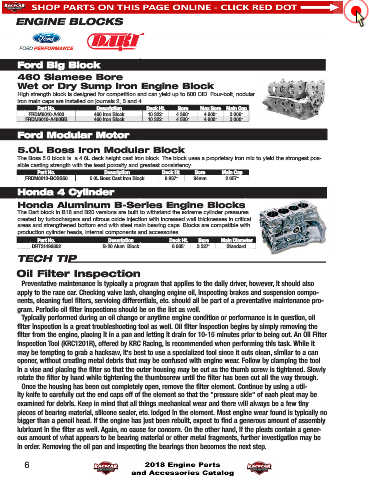

ENGINE BLOCKS

Ford Big Block

460 Siamese Bore

Wet or Dry Sump Iron Engine Block

High strength block is designed for competition and can yield up to 600 CID. Four-bolt, nodular

iron main caps are installed on journals 2, 3 and 4.

Part No. Description Deck Ht. Bore Max Bore Main Cap

FRDM6010-A460 460 Iron Block 10.322" 4.360" 4.600" 3.000"

FRDM6010-A460BB 460 Iron Block 10.322" 4.500" 4.600" 3.000"

Ford Modular Motor

5.0L Boss Iron Modular Block

The Boss 5.0 block is a 4.6L deck height cast iron block. The block uses a proprietary iron mix to yield the strongest pos-

sible casting strength with the least porosity and greatest consistency

Part No. Description Deck Ht. Bore Main Cap

FRDM6010-BOSS50 5.0L Boss Cast Iron Block 8.937" 94mm 2.657"

Honda 4 Cylinder

Honda Aluminum B-Series Engine Blocks

The Dart block in B18 and B20 versions are built to withstand the extreme cylinder pressures

created by turbochargers and nitrous oxide injection with increased wall thicknesses in critical

areas and strengthened bottom end with steel main bearing caps. Blocks are compatible with

production cylinder heads, internal components and accessories.

Part No. Description Deck Ht. Bore Main Diameter

DRT31496802 B-20 Alum. Block 8.685" 3.327" Standard

TECH TIP

Oil Filter Inspection

Preventative maintenance is typically a program that applies to the daily driver, however, it should also

apply to the race car. Checking valve lash, changing engine oil, inspecting brakes and suspension compo-

nents, cleaning fuel filters, servicing differentials, etc. should all be part of a preventative maintenance pro-

gram. Periodic oil filter inspections should be on the list as well.

Typically performed during an oil change or anytime engine condition or performance is in question, oil

filter inspection is a great troubleshooting tool as well. Oil filter inspection begins by simply removing the

filter from the engine, placing it in a pan and letting it drain for 10-15 minutes prior to being cut. An Oil Filter

Inspection Tool (KRC1201R), offered by KRC Racing, is recommended when performing this task. While it

may be tempting to grab a hacksaw, it's best to use a specialized tool since it cuts clean, similar to a can

opener, without creating metal debris that may be confused with engine wear. Follow by clamping the tool

in a vise and placing the filter so that the outer housing may be cut as the thumb screw is tightened. Slowly

rotate the filter by hand while tightening the thumbscrew until the filter has been cut all the way through.

Once the housing has been cut completely open, remove the filter element. Continue by using a util-

ity knife to carefully cut the end caps off of the element so that the "pressure side" of each pleat may be

examined for debris. Keep in mind that all things mechanical wear and there will always be a few tiny

pieces of bearing material, silicone sealer, etc. lodged in the element. Most engine wear found is typically no

bigger than a pencil head. If the engine has just been rebuilt, expect to find a generous amount of assembly

lubricant in the filter as well. Again, no cause for concern. On the other hand, if the pleats contain a gener-

ous amount of what appears to be bearing material or other metal fragments, further investigation may be

in order. Removing the oil pan and inspecting the bearings then becomes the next step.

6 2018 ENGINE BUILDER CATALOG