Page 6 - Newsletter_November2017

P. 6

Safety Corner

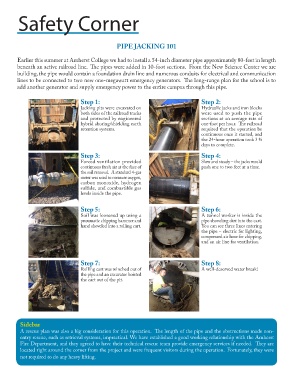

PIPE JACKING 101

Earlier this summer at Amherst College we had to install a 54-inch diameter pipe approximately 80-feet in length

beneath an active railroad line. The pipes were added in 10-foot sections. From the New Science Center we are

building, the pipe would contain a foundation drain line and numerous conduits for electrical and communication

lines to be connected to two new one-megawatt emergency generators. The long-range plan for the school is to

add another generator and supply emergency power to the entire campus through this pipe.

Step 1: Step 2:

Jacking pits were excavated on Hydraulic jacks and iron blocks

both sides of the railroad tracks were used to push the pipe

and protected by engineered sections at an average rate of

hybrid shoring/shielding earth one-foot per hour. The railroad

retention systems. required that the operation be

continuous once it started, and

the 24-hour operation took 3 ½

days to complete.

Step 3: Step 4:

Forced ventilation provided Slow and steady – the jacks would

continuous fresh air at the face of push one to two feet at a time.

the soil removal. A standard 4-gas

meter was used to measure oxygen,

carbon monoxide, hydrogen

sulfide, and combustible gas

levels inside the pipe.

Step 5: Step 6:

Soil was loosened up using a A tunnel worker is inside the

pneumatic chipping hammer and pipe shoveling dirt into the cart.

hand shoveled into a rolling cart. You can see three lines entering

the pipe – electric for lighting,

compressed air hose for chipping,

and an air line for ventilation.

Step 7: Step 8:

Rolling cart was winched out of A well-deserved water break!

the pipe and an excavator hoisted

the cart out of the pit.

Sidebar

A rescue plan was also a big consideration for this operation. The length of the pipe and the obstructions made non-

entry rescue, such as retrieval systems, impractical. We have established a good working relationship with the Amherst

Fire Department, and they agreed to have their technical rescue team provide emergency services if needed. They are

located right around the corner from the project and were frequent visitors during the operation. Fortunately, they were

not required to do any heavy lifting.