Page 39 - Router Boss Manual

P. 39

Cutting mortises

and tenons

You saw a couple of ways to cut grooves in flat

stock when we put the bottom panel in a drawer (see

pages 31 and 32), but there are times you need to cut

grooves in the edge of a piece of stock, such as in rails

(horizontal top and bottom pieces) and stiles (vertical

side pieces) on a paneled door. In this section we’ll

show how to cut the grooves, mortises and tenons for a

paneled door. The mortising techniques we show can

also be used for other projects such as mortising a ta-

ble leg to accept a tenoned apron rail or stretcher. With

every mortise, you’ll need to cut a matching tenon to

complete the joint. The Router Boss handles these tasks

with precision and ease.

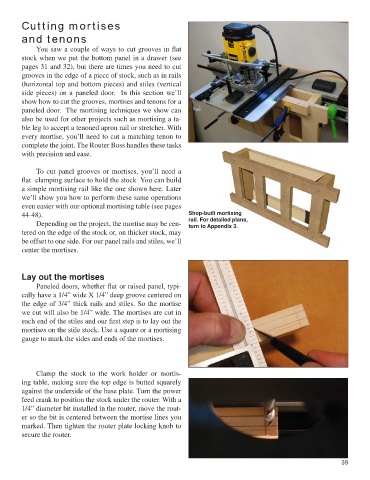

To cut panel grooves or mortises, you’ll need a

flat clamping surface to hold the stock You can build

a simple mortising rail like the one shown here. Later

we’ll show you how to perform these same operations

even easier with our optional mortising table (see pages

44-48). Shop-built mortising

Depending on the project, the mortise may be cen- rail. For detailed plans,

turn to Appendix 3.

tered on the edge of the stock or, on thicker stock, may

be offset to one side. For our panel rails and stiles, we’ll

center the mortises.

Lay out the mortises

Paneled doors, whether flat or raised panel, typi-

cally have a 1/4” wide X 1/4” deep groove centered on

the edge of 3/4” thick rails and stiles. So the mortise

we cut will also be 1/4” wide. The mortises are cut in

each end of the stiles and our first step is to lay out the

mortises on the stile stock. Use a square or a mortising

gauge to mark the sides and ends of the mortises.

Clamp the stock to the work holder or mortis-

ing table, making sure the top edge is butted squarely

against the underside of the base plate. Turn the power

feed crank to position the stock under the router. With a

1/4” diameter bit installed in the router, move the rout-

er so the bit is centered between the mortise lines you

marked. Then tighten the router plate locking knob to

secure the router.

39