Page 11 - Moldex3d training Manual

P. 11

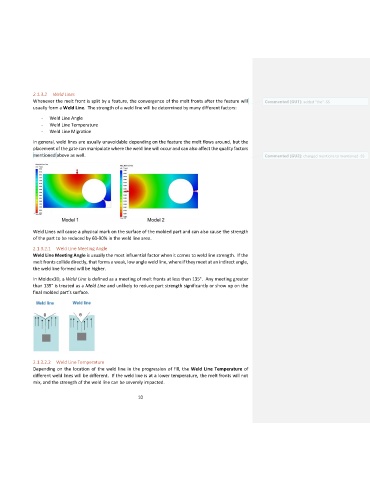

2.1.3.2 Weld Lines

Whenever the melt front is split by a feature, the convergence of the melt fronts after the feature will Commented [GU1]: added "the" -SS

usually form a Weld Line. The strength of a weld line will be determined by many different factors:

- Weld Line Angle

- Weld Line Temperature

- Weld Line Migration

In general, weld lines are usually unavoidable depending on the feature the melt flows around, but the

placement of the gate can manipulate where the weld line will occur and can also affect the quality factors

mentioned above as well. Commented [GU2]: changed mentions to mentioned -SS

Weld Lines will cause a physical mark on the surface of the molded part and can also cause the strength

of the part to be reduced by 60-90% in the weld line area.

2.1.3.2.1 Weld Line Meeting Angle

Weld Line Meeting Angle is usually the most influential factor when it comes to weld line strength. If the

melt fronts collide directly, that forms a weak, low angle weld line, where if they meet at an indirect angle,

the weld line formed will be higher.

In Moldex3D, a Weld Line is defined as a meeting of melt fronts at less than 135°. Any meeting greater

than 135° is treated as a Meld Line and unlikely to reduce part strength significantly or show up on the

final molded part’s surface.

2.1.3.2.2 Weld Line Temperature

Depending on the location of the weld line in the progression of fill, the Weld Line Temperature of

different weld lines will be different. If the weld line is at a lower temperature, the melt fronts will not

mix, and the strength of the weld line can be severely impacted.

10