Page 13 - Moldex3d training Manual

P. 13

2.1.4.1 eDesign vs Solid

The eDesign meshing style is the most basic type of meshing available and can be generated automatically,

having the least amount of manual interaction after all modelling components are brought into the

application.

Boundary Layer Mesh (BLM) is a more advanced meshing style which gives the user control over the solid

mesh layout using various meshing controls, which will be mentioned later. This semi-automatic meshing

approach is the current best practice for meshing in Moldex3D and is the approach described below.

There are three (3) main differences between the eDesign and BLM meshing styles:

1) Element count – Due to the nature of Voxel elements, the element count tends to be much higher

than BLM meshing. On average, the calculation time for eDesign is 30-40% longer than BLM due

to the higher element count.

2) Mesh resolution – The Boundary Layer Mesh style gets its name from the layer of high-quality

prism elements which lie near the surface of the part. These elements allow for the resolution of

the results through the thickness of the part to be better. The eDesign voxel elements will

produce results which may be ambiguous and blurry through the thickness.

3) Meshing Time – As mentioned before, eDesign meshing is completely automatic, whereas BLM is

semi-automatic, requiring the user to input some parameters and check mesh quality. Meshing

time is typically 10-20% longer with BLM meshing.

Overall, the simulation time reduction and resolution of results outweigh the pre-processing time, making

BLM meshing an overall more efficient approach to meshing.

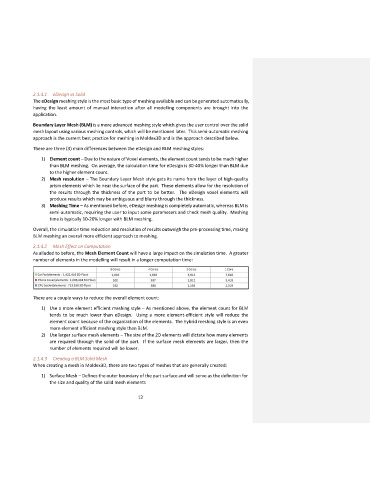

2.1.4.2 Mesh Effect on Computation

As alluded to before, the Mesh Element Count will have a large impact on the simulation time. A greater

number of elements in the modelling will result in a longer computation time:

There are a couple ways to reduce the overall element count:

1) Use a more element efficient meshing style – As mentioned above, the element count for BLM

tends to be much lower than eDesign. Using a more element-efficient style will reduce the

element count because of the organization of the elements. The hybrid meshing style is an even

more element efficient meshing style than BLM.

2) Use larger surface mesh elements – The size of the 2D elements will dictate how many elements

are required through the solid of the part. If the surface mesh elements are larger, then the

number of elements required will be lower.

2.1.4.3 Creating a BLM Solid Mesh

When creating a mesh in Moldex3D, there are two types of meshes that are generally created:

1) Surface Mesh – Defines the outer boundary of the part surface and will serve as the definition for

the size and quality of the solid mesh elements

12