Page 15 - Moldex3d training Manual

P. 15

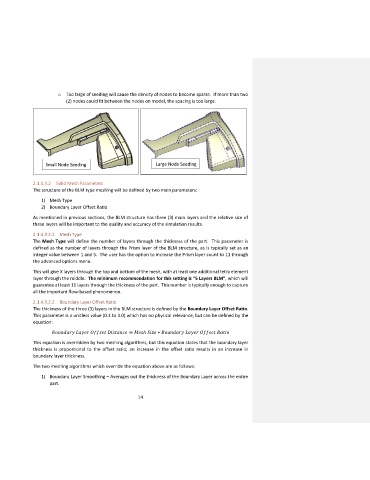

o Too large of seeding will cause the density of nodes to become sparse. If more than two

(2) nodes could fit between the nodes on model, the spacing is too large.

Small Node Seeding Large Node Seeding

2.1.4.3.2 Solid Mesh Parameters

The structure of the BLM type meshing will be defined by two main parameters:

1) Mesh Type

2) Boundary Layer Offset Ratio

As mentioned in previous sections, the BLM structure has three (3) main layers and the relative size of

these layers will be important to the quality and accuracy of the simulation results.

2.1.4.3.2.1 Mesh Type

The Mesh Type will define the number of layers through the thickness of the part. This parameter is

defined as the number of layers through the Prism layer of the BLM structure, as is typically set as an

integer value between 1 and 5. The user has the option to increase the Prism layer count to 11 through

the advanced options menu.

This will give X layers through the top and bottom of the mesh, with at least one additional tetra element

layer through the middle. The minimum recommendation for this setting is “5 Layers BLM”, which will

guarantee at least 11 layers through the thickness of the part. This number is typically enough to capture

all the important flow-based phenomenon.

2.1.4.3.2.2 Boundary Layer Offset Ratio

The thickness of the three (3) layers in the BLM structure is defined by the Boundary Layer Offset Ratio.

This parameter is a unitless value (0.1 to 3.0) which has no physical relevance, but can be defined by the

equation:

= ℎ ∗

This equation is overridden by two meshing algorithms, but this equation states that the boundary layer

thickness is proportional to the offset ratio; an increase in the offset ratio results in an increase in

boundary layer thickness.

The two meshing algorithms which override the equation above are as follows:

1) Boundary Layer Smoothing – Averages out the thickness of the Boundary Layer across the entire

part.

14