Page 39 - Tunnel Support Components

P. 39

TUNNEL SUPPORT COMPONENTS

Installation

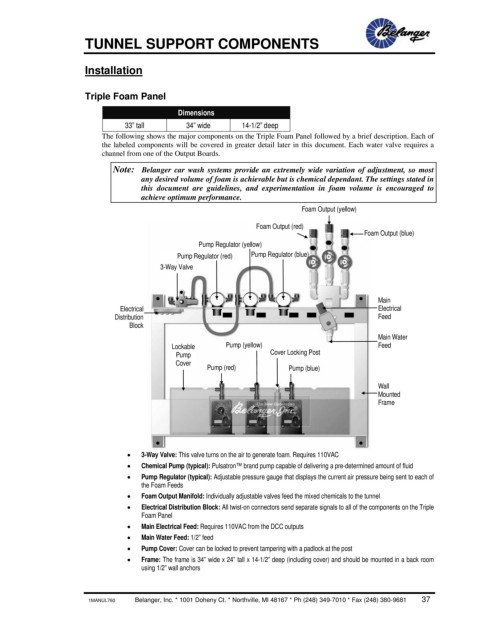

Triple Foam Panel

Dimensions

33” tall 34” wide 14-1/2” deep

The following shows the major components on the Triple Foam Panel followed by a brief description. Each of

the labeled components will be covered in greater detail later in this document. Each water valve requires a

channel from one of the Output Boards.

Note: Belanger car wash systems provide an extremely wide variation of adjustment, so most

any desired volume of foam is achievable but is chemical dependant. The settings stated in

this document are guidelines, and experimentation in foam volume is encouraged to

achieve optimum performance.

Foam Output (yellow)

Foam Output (red)

Foam Output (blue)

Pump Regulator (yellow)

Pump Regulator (red) Pump Regulator (blue)

3-Way Valve

Main

Electrical Electrical

Distribution Feed

Block

Main Water

Lockable Pump (yellow) Feed

Pump Cover Locking Post

Cover

Pump (red) Pump (blue)

Wall

Mounted

Frame

• 3-Way Valve: This valve turns on the air to generate foam. Requires 110VAC

• Chemical Pump (typical): Pulsatron™ brand pump capable of delivering a pre-determined amount of fluid

• Pump Regulator (typical): Adjustable pressure gauge that displays the current air pressure being sent to each of

the Foam Feeds

• Foam Output Manifold: Individually adjustable valves feed the mixed chemicals to the tunnel

• Electrical Distribution Block: All twist-on connectors send separate signals to all of the components on the Triple

Foam Panel

• Main Electrical Feed: Requires 110VAC from the DCC outputs

• Main Water Feed: 1/2” feed

• Pump Cover: Cover can be locked to prevent tampering with a padlock at the post

• Frame: The frame is 34” wide x 24” tall x 14-1/2” deep (including cover) and should be mounted in a back room

using 1/2” wall anchors

1MANUL760 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 37