Page 29 - DuraFlo™ 18 GPM Pump Station

P. 29

DURAFLO™ 18 GPM PUMPING STATIONS

Maintenance

Drive Belt Replacement and Tightening

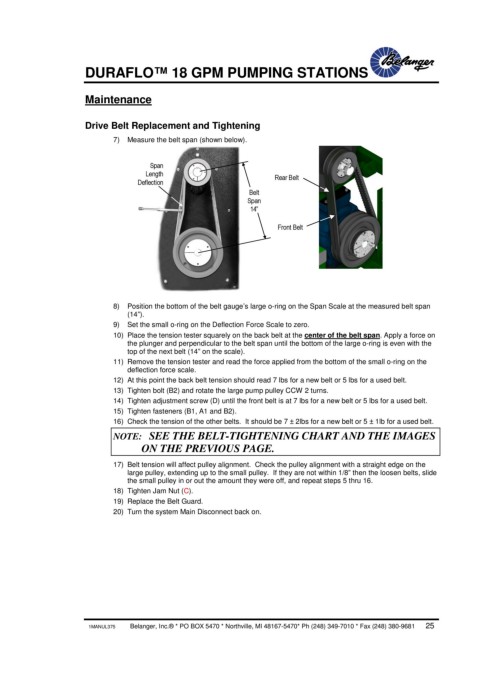

7) Measure the belt span (shown below).

Span

Length Rear Belt

Deflection

Belt

Span

14”

Front Belt

8) Position the bottom of the belt gauge’s large o-ring on the Span Scale at the measured belt span

(14”).

9) Set the small o-ring on the Deflection Force Scale to zero.

10) Place the tension tester squarely on the back belt at the center of the belt span. Apply a force on

the plunger and perpendicular to the belt span until the bottom of the large o-ring is even with the

top of the next belt (14” on the scale).

11) Remove the tension tester and read the force applied from the bottom of the small o-ring on the

deflection force scale.

12) At this point the back belt tension should read 7 lbs for a new belt or 5 lbs for a used belt.

13) Tighten bolt (B2) and rotate the large pump pulley CCW 2 turns.

14) Tighten adjustment screw (D) until the front belt is at 7 lbs for a new belt or 5 lbs for a used belt.

15) Tighten fasteners (B1, A1 and B2).

16) Check the tension of the other belts. It should be 7 ± 2lbs for a new belt or 5 ± 1lb for a used belt.

NOTE: SEE THE BELT-TIGHTENING CHART AND THE IMAGES

ON THE PREVIOUS PAGE.

17) Belt tension will affect pulley alignment. Check the pulley alignment with a straight edge on the

large pulley, extending up to the small pulley. If they are not within 1/8” then the loosen belts, slide

the small pulley in or out the amount they were off, and repeat steps 5 thru 16.

18) Tighten Jam Nut (C).

19) Replace the Belt Guard.

20) Turn the system Main Disconnect back on.

1MANUL375 Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470* Ph (248) 349-7010 * Fax (248) 380-9681 25