Page 40 - Wash Around

P. 40

WASH AROUND

Startup

Initial

This section is dedicated to assisting you in the initial startup procedures. The settings may vary after the

initial startup.

Boom Pressure

Pressure settings on each boom will effect how fast the booms move in and out, and must be set before

setting the flow controls. Open both flow controls on each boom extend cylinder by completely turning

them counter-clockwise.

1) Set initial boom extend pressure as follows:

• Driver side: 20

• Passenger side: 40

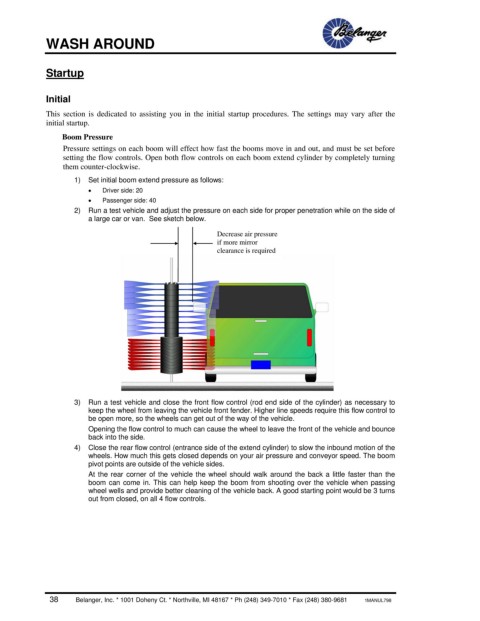

2) Run a test vehicle and adjust the pressure on each side for proper penetration while on the side of

a large car or van. See sketch below.

Decrease air pressure

if more mirror

clearance is required

3) Run a test vehicle and close the front flow control (rod end side of the cylinder) as necessary to

keep the wheel from leaving the vehicle front fender. Higher line speeds require this flow control to

be open more, so the wheels can get out of the way of the vehicle.

Opening the flow control to much can cause the wheel to leave the front of the vehicle and bounce

back into the side.

4) Close the rear flow control (entrance side of the extend cylinder) to slow the inbound motion of the

wheels. How much this gets closed depends on your air pressure and conveyor speed. The boom

pivot points are outside of the vehicle sides.

At the rear corner of the vehicle the wheel should walk around the back a little faster than the

boom can come in. This can help keep the boom from shooting over the vehicle when passing

wheel wells and provide better cleaning of the vehicle back. A good starting point would be 3 turns

out from closed, on all 4 flow controls.

38 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL798