Page 37 - Jet Pumping Station

P. 37

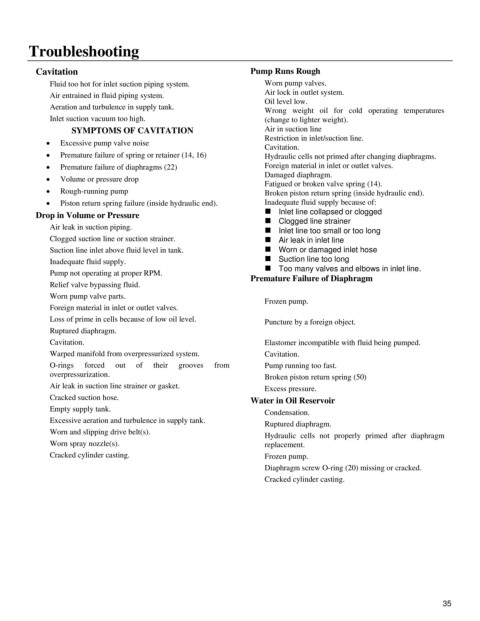

Troubleshooting

Cavitation Pump Runs Rough

Fluid too hot for inlet suction piping system. Worn pump valves.

Air lock in outlet system.

Air entrained in fluid piping system. Oil level low.

Aeration and turbulence in supply tank. Wrong weight oil for cold operating temperatures

Inlet suction vacuum too high. (change to lighter weight).

SYMPTOMS OF CAVITATION Air in suction line

Restriction in inlet/suction line.

• Excessive pump valve noise

Cavitation.

• Premature failure of spring or retainer (14, 16) Hydraulic cells not primed after changing diaphragms.

• Premature failure of diaphragms (22) Foreign material in inlet or outlet valves.

Damaged diaphragm.

• Volume or pressure drop

Fatigued or broken valve spring (14).

• Rough-running pump Broken piston return spring (inside hydraulic end).

• Piston return spring failure (inside hydraulic end). Inadequate fluid supply because of:

Drop in Volume or Pressure Inlet line collapsed or clogged

Clogged line strainer

Air leak in suction piping. Inlet line too small or too long

Clogged suction line or suction strainer. Air leak in inlet line

Suction line inlet above fluid level in tank. Worn or damaged inlet hose

Inadequate fluid supply. Suction line too long

Pump not operating at proper RPM. Too many valves and elbows in inlet line.

Premature Failure of Diaphragm

Relief valve bypassing fluid.

Worn pump valve parts.

Frozen pump.

Foreign material in inlet or outlet valves.

Loss of prime in cells because of low oil level. Puncture by a foreign object.

Ruptured diaphragm.

Cavitation. Elastomer incompatible with fluid being pumped.

Warped manifold from overpressurized system. Cavitation.

O-rings forced out of their grooves from Pump running too fast.

overpressurization. Broken piston return spring (50)

Air leak in suction line strainer or gasket. Excess pressure.

Cracked suction hose. Water in Oil Reservoir

Empty supply tank. Condensation.

Excessive aeration and turbulence in supply tank. Ruptured diaphragm.

Worn and slipping drive belt(s).

Hydraulic cells not properly primed after diaphragm

Worn spray nozzle(s). replacement.

Cracked cylinder casting. Frozen pump.

Diaphragm screw O-ring (20) missing or cracked.

Cracked cylinder casting.

35