Page 51 - Gyro Wrap™ Signature ® Series

P. 51

GYRO WRAP™ Signature ® Series

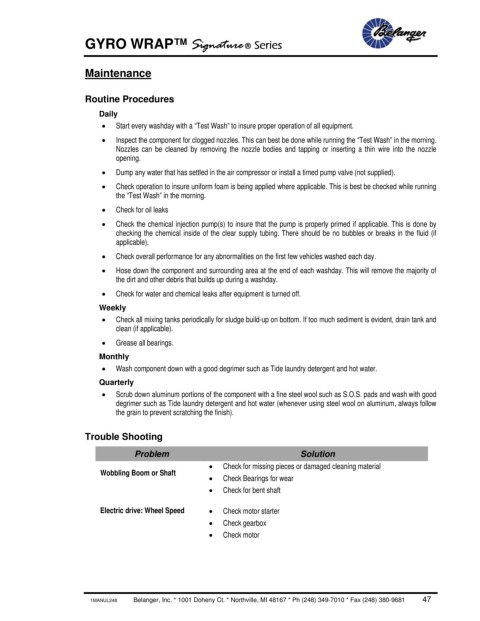

Maintenance

Routine Procedures

Daily

• Start every washday with a “Test Wash” to insure proper operation of all equipment.

• Inspect the component for clogged nozzles. This can best be done while running the “Test Wash” in the morning.

Nozzles can be cleaned by removing the nozzle bodies and tapping or inserting a thin wire into the nozzle

opening.

• Dump any water that has settled in the air compressor or install a timed pump valve (not supplied).

• Check operation to insure uniform foam is being applied where applicable. This is best be checked while running

the “Test Wash” in the morning.

• Check for oil leaks

• Check the chemical injection pump(s) to insure that the pump is properly primed if applicable. This is done by

checking the chemical inside of the clear supply tubing. There should be no bubbles or breaks in the fluid (if

applicable).

• Check overall performance for any abnormalities on the first few vehicles washed each day.

• Hose down the component and surrounding area at the end of each washday. This will remove the majority of

the dirt and other debris that builds up during a washday.

• Check for water and chemical leaks after equipment is turned off.

Weekly

• Check all mixing tanks periodically for sludge build-up on bottom. If too much sediment is evident, drain tank and

clean (if applicable).

• Grease all bearings.

Monthly

• Wash component down with a good degrimer such as Tide laundry detergent and hot water.

Quarterly

• Scrub down aluminum portions of the component with a fine steel wool such as S.O.S. pads and wash with good

degrimer such as Tide laundry detergent and hot water (whenever using steel wool on aluminum, always follow

the grain to prevent scratching the finish).

Trouble Shooting

Problem Solution

• Check for missing pieces or damaged cleaning material

Wobbling Boom or Shaft

• Check Bearings for wear

• Check for bent shaft

Electric drive: Wheel Speed • Check motor starter

• Check gearbox

• Check motor

1MANUL248 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 47