Page 61 - QuickFire® Wrap Around Signature® Series

P. 61

QUICKFIRE® Signature ® Series

Maintenance

General Replacement Information

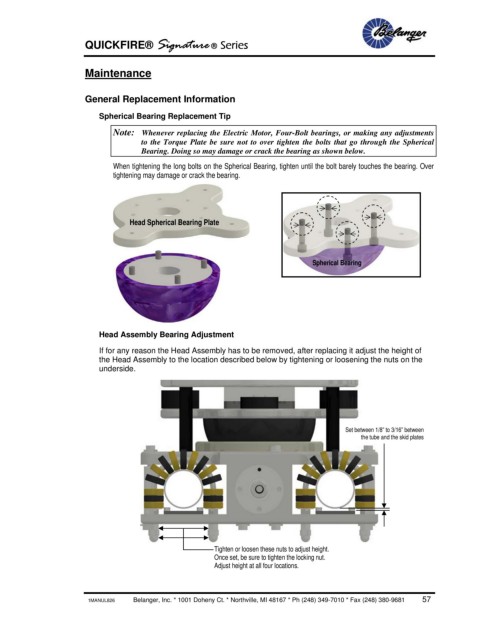

Spherical Bearing Replacement Tip

Note: Whenever replacing the Electric Motor, Four-Bolt bearings, or making any adjustments

to the Torque Plate be sure not to over tighten the bolts that go through the Spherical

Bearing. Doing so may damage or crack the bearing as shown below.

When tightening the long bolts on the Spherical Bearing, tighten until the bolt barely touches the bearing. Over

tightening may damage or crack the bearing.

Head Spherical Bearing Plate

Spherical Bearing

Head Assembly Bearing Adjustment

If for any reason the Head Assembly has to be removed, after replacing it adjust the height of

the Head Assembly to the location described below by tightening or loosening the nuts on the

underside.

Set between 1/8” to 3/16” between

the tube and the skid plates

Tighten or loosen these nuts to adjust height.

Once set, be sure to tighten the locking nut.

Adjust height at all four locations.

1MANUL826 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 57