Page 30 - stanochny park

P. 30

PROFESSIONAL ADVICE PROFESSIONAL ADVICE

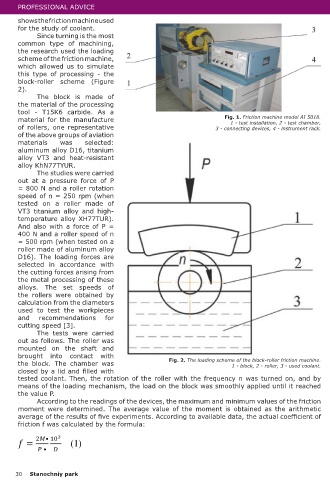

shows the friction machine used

for the study of coolant. where M is the average value of Table 1. The results of studies of lubricating action

Since turning is the most the moment of friction, N • m; various brands of coolant.

common type of machining, P is the applied load, N; Coolant mixture mark Kcм

the research used the loading D is the diameter of the

scheme of the friction machine, roller, mm WT3 D16 KhN77TYUR

which allowed us to simulate For testing, 10% aqueous coolant Without cooling mixture 0,405 0,675 0,620

this type of processing - the solutions of several grades were Addinol WH430 0,505 0,090 0,545

block-roller scheme (Figure used: Addinol WH430, Blasocut Blasocut 4000 0,485 0,096 0,545

2). 4000, Ukrinol-1M, Sinertek ML, Ukrinol-1М 0,490 0,070 0,570

The block is made of Rosoil-500, Akvol-6, Ekol-B2. In

the material of the processing addition, the tests were carried Sinertek ML 0,450 0,098 0,584

tool - T15K6 carbide. As a out without the use of coolant. Rosoil-500 0,505 0,060 0,555

material for the manufacture Fig. 1. Friction machine model AI 5018. The research results are Akvol-6 0,520 0,060 0,520

1 - test installation, 2 - test chamber,

of rollers, one representative 3 - connecting devices, 4 - instrument rack. shown in table 1. Ekol-B2 0,404 0,065 0,521

of the above groups of aviation The results of the studies

materials was selected: allow us to evaluate the lubricating

aluminum alloy D16, titanium effect of the tested cooling mixture in the processing of the presented groups of aviation

alloy VT3 and heat-resistant materials. The data obtained provide the ability to select the most technologically effective

alloy KhN77TYUR. coolant for processing the given materials for lubricating action.

The studies were carried The effectiveness of the application of each brand of cooling mixture must be determined

out at a pressure force of P in comparison with processing without the use of coolant. The value of the effectiveness of Kcm

= 800 N and a roller rotation lubricating action in the processing of various materials is determined by the formula:

speed of n = 250 rpm (when

tested on a roller made of

VT3 titanium alloy and high-

temperature alloy ХН77TUR). where fСОЖ– coefficient of friction using tested coolant; .

And also with a force of P = fбезСОЖ – coefficient of friction without the use of coolant.

400 N and a roller speed of n The lower the value of Kcm, the more efficient this brand is when processing the tested

= 500 rpm (when tested on a material. Table 2 presents the effectiveness of the tested grades of coolant lubricating action.

roller made of aluminum alloy From [4] it is known that when processing at low speeds, when the coolant is best in

D16). The loading forces are the cutting zone, the lubricating effect of the coolant has the greatest effect. Thus, the use of

selected in accordance with coolant with a high lubricating effect is advisable when roughing.

the cutting forces arising from Table 2 shows:

the metal processing of these 1) when machining VT3 titanium alloy, the most lubricating lubricant is Ekol-B2 coolant

alloys. The set speeds of (Kcm = 0.998), the use of other coolants is inefficient, because their coefficient Kcm is more than one;

the rollers were obtained by 2) when processing the aluminum alloy D16

calculation from the diameters Table 2. The effectiveness of various grades of coolant - Rosoil-500, Akvol-6 (Kcm = 0.089) and Ekol-B2

used to test the workpieces by lubricating action. (Kcm = 0.096);

and recommendations for Coolant mixture mark Kсм 3) when processing the heat-resistant alloy

cutting speed [3]. WT3 D16 KhN77TYUR KhN77TYUR - Akvol-6 (Kcm = 0.839) and Ekol-B2

The tests were carried Addinol WH430 1,247 0,133 0,879 (Kcm = 0.840).

out as follows. The roller was Blasocut 4000 1,198 0,142 0,879 Study of the cooling effect of coolant

mounted on the shaft and Ukrinol-1М 1,210 0,104 0,919 The cooling effect, as well as the lubricating

brought into contact with Sinertek ML 1,111 0,145 0,942 one, is evaluated during tests both on metal-

the block. The chamber was Fig. 2. The loading scheme of the block-roller friction machine. Rosoil-500 1,247 0,089 0,895 cutting machines during processing and on

1 - block, 2 - roller, 3 - used coolant.

closed by a lid and filled with Akvol-6 1,248 0,089 0,839 specialized plants. The use of such plants reduces

tested coolant. Then, the rotation of the roller with the frequency n was turned on, and by Ekol-B2 0,998 0,096 0,840 material consumption, coolant and test time, and

means of the loading mechanism, the load on the block was smoothly applied until it reached also eliminates the influence of other actions.

the value P. Therefore, the cooling effect of the coolant was evaluated according to the results of tests at

According to the readings of the devices, the maximum and minimum values of the friction the bench, a diagram of which is shown in Figure 3.

moment were determined. The average value of the moment is obtained as the arithmetic

average of the results of five experiments. According to available data, the actual coefficient of Examination with the help of this stand the cooling effect of various cooling mixture allows

friction f was calculated by the formula: the choice of cooling mixture with the greatest cooling ability. The studies were carried out on

the coolant brands used in the tests of the lubricating action. In addition, studies were carried

out without the use of cooling mixture. .

The tests were carried out as follows. The studied coolant was poured into a container 5

(Figure 2) and, using a magnetic stirrer 3, was constantly mixed. The temperature sensor 4 was

30 Stanochniy park Stanochniy park 31