Page 32 - stanochny park

P. 32

PROFESSIONAL ADVICE PROFESSIONAL ADVICE

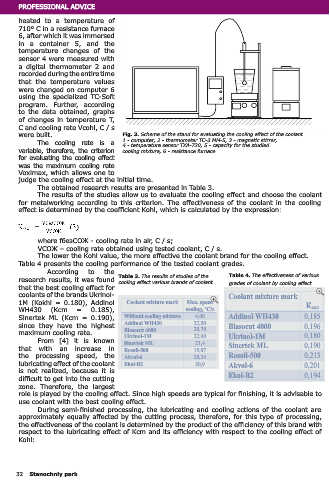

heated to a temperature of Table 5. The effectiveness of various grades of

710° C in a resistance furnace coolant on lubricating and cooling actions. .

6, after which it was immersed The lower the K value, the more efficient Coolant mixture mark

in a container 5, and the the coolant grade is in terms of a comprehensive WT3 D16 K

temperature changes of the performance indicator. Table 5 presents the Addinol WH430 0,230 0,025 KhN77TYUR

0,162

sensor 4 were measured with effectiveness of the cooling mixture in the lubricating Blasocut 4000 0,235 0,028 0,172

a digital thermometer 2 and and cooling actions of K for processing all tested Ukrinol-1М 0,217 0,019 0,165

recorded during the entire time materials. Sinertek ML 0,211 0,028 0,179

that the temperature values Analysis of table 5 showed that: Rosoil-500 0,265 0,019 0,191

were changed on computer 6 1) when machining VT3 titanium alloy, the most Akvol-6 0,258 0,018 0,168

using the specialized TC-Soft effective in terms of a comprehensive performance Ekol-B2 0,194 0,019 0,163

program. Further, according indicator is the coolant of the Ekol-B2 grade (K =

to the data obtained, graphs 0.194);

of changes in temperature T, 2) when processing an aluminum alloy D16

C and cooling rate Vcohl, C / s - Akvol-6 (K = 0.018), Ukrinol-1M, Rosoil-500 and

were built. Fig. 3. Scheme of the stand for evaluating the cooling effect of the coolant. Ekol-B2 (K = 0.019);

The cooling rate is a 1 - computer, 2 - thermometer TC-3 MM-5, 3 - magnetic stirrer, 3) during processing of the heat-resistant alloy

variable, therefore, the criterion 4 - temperature sensor TXA-720, 5 - capacity for the studied KhN77TYUR - Addinol WH430 (K = 0.162), Ekol-B2

cooling mixture, 6 - resistance furnace

for evaluating the cooling effect (K = 0.163), Ukrinol-1M (K = 0.165).

was the maximum cooling rate

Voxlmax, which allows one to

judge the cooling effect at the initial time.

The obtained research results are presented in Table 3.

The results of the studies allow us to evaluate the cooling effect and choose the coolant

for metalworking according to this criterion. The effectiveness of the coolant in the cooling

effect is determined by the coefficient Kohl, which is calculated by the expression:

where fбезСОЖ - cooling rate in air, C / s;

VСОЖ – cooling rate obtained using tested coolant, C / s.

The lower the Kohl value, the more effective the coolant brand for the cooling effect.

Table 4 presents the cooling performance of the tested coolant grades.

According to the

research results, it was found Table 3. The results of studies of the Table 4. The effectiveness of various

cooling effect various brands of coolant.

grades of coolant by cooling effect.

that the best cooling effect for

coolants of the brands Ukrinol- Coolant mixture mark

1M (Kokhl = 0.180), Addinol Coolant mixture mark Max. speed Conclusions

WH430 (Kcm = 0.185), cooling, ºС/с Кохл The paper carried out experimental studies of the main functional actions tested by the

Sinertek ML (Kcm = 0.190), Without cooling mixture 4,06 Addinol WH430 0,185 cooling mixture. The presented results allow us to choose the most effective brand of coolant

since they have the highest Addinol WH430 22,00 Blasocut 4000 0,196 mixture for various modes of processing aviation materials. The results of the work will be

maximum cooling rate. Blasocut 4000 20,70 Ukrinol-1М 0,180 especially useful in the production of aircraft parts, since the use of an effective cooling mixture

Ukrinol-1М

22,60

From [4] it is known Sinertek ML 21,4 provides the greatest possible reduction in friction and average cutting temperature, which

that with an increase in Rosoil-500 19,07 Sinertek ML 0,190 leads to an extension of the tool life, lower cutting forces, reduced surface roughness, and

the processing speed, the Akvol-6 20,24 Rosoil-500 0,213 improved machining accuracy.

lubricating effect of the coolant Ekol-B2 20,9 Akvol-6 0,201

is not realized, because it is Ekol-B2 0,194 A.G. Kissel, D.S. Rechenko,

difficult to get into the cutting Yu.V. Titov, V.R. Titov,

zone. Therefore, the largest E.N. Kopylova.

role is played by the cooling effect. Since high speeds are typical for finishing, it is advisable to

use coolant with the best cooling effect. .

During semi-finished processing, the lubricating and cooling actions of the coolant are References:

.

approximately equally affected by the cutting process, therefore, for this type of processing, 1. Chernobay S.P. Development and research of resource-saving technologies for metal cutting for the manufacture of

the effectiveness of the coolant is determined by the product of the efficiency of this brand with aircraft parts: dis. Cand. tech. Sciences: 05.07.02 / Sergey Petrovich Chernobay. - Komsomolsk-on-Amur, 2004. 154 p.

2. Evseev D.G., Popov A.Yu. Measurement of cutting forces during turning: Methodological guidelines for laboratory

respect to the lubricating effect of Kcm and its efficiency with respect to the cooling effect of work in the discipline «Metal cutting» M.: MIIT, 2006. - 34 p.

Kohl: 3. Kosilova, A.G. Reference technologist-machine builder. In 2 t./ed. A.G. Kosilova, R.K. Mescherikova. - M.:

Mechanical Engineering, 1986. 496 p.

4. Shashin A.D. Study of the influence of coolant on the process of interaction between tool and workpiece during

metal cutting: dis. Cand. tech. Sciences: 05.03.01 / Andrey Dmitrievich Shashin. M., 2003.118 p.

32 Stanochniy park Stanochniy park 33