Page 4 - Parkside Gasification & Pellet Plant Report 081117_Neat

P. 4

PARKSIDE TIMBER DIVISION – WASTE TO

ENERGY PLANT CONCEPT

Recycling Technologies Group Pty Ltd (RTG) have been asked to evaluate the potential waste stream

from the Parkside Timber operations and propose some ideas for a biomass waste to energy plant

and utilisation of the waste resource.

In this desktop study, we have only considered the biomass available from the Wondai Sawmill and

Dry Mill operations. The Wondai Dry Mill operations have the largest electrical energy requirements

and have thermal energy requirements for the operation of the kilns.

Therefore, it makes sense to commence the study at this site first.

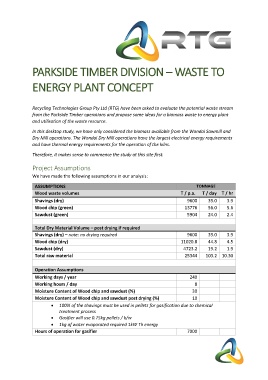

Project Assumptions

We have made the following assumptions in our analysis:

ASSUMPTIONS TONNAGE

Wood waste volumes T / p.a. T / day T / hr

Shavings (dry) 9600 39.0 3.9

Wood chip (green) 13776 56.0 5.6

Sawdust (green) 5904 24.0 2.4

Total Dry Material Volume – post drying if required

Shavings (dry) – note: no drying required 9600 39.0 3.9

Wood chip (dry) 11020.8 44.8 4.5

Sawdust (dry) 4723.2 19.2 1.9

Total raw material 25344 103.2 10.30

Operation Assumptions

Working days / year 240

Working hours / day 8

Moisture Content of Wood chip and sawdust (%) 30

Moisture Content of Wood chip and sawdust post drying (%) 10

• 100% of the shavings must be used in pellets for gasification due to chemical

treatment process

• Gasifier will use 0.75kg pellets / k/w

• 1kg of water evaporated required 1kW Th energy

Hours of operation for gasifier 7000