Page 7 - Parkside Gasification & Pellet Plant Report 081117_Neat

P. 7

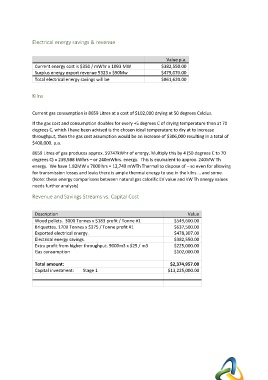

Electrical energy savings & revenue

Value p.a.

Current energy cost is $350 / mWhr x 1093 MW $382,550.00

Surplus energy export revenue 5323 x $90Mw $479,070.00

Total electrical energy savings will be $861,620.00

Kilns

Current gas consumption is 8659 Litres at a cost of $102,000 drying at 50 degrees Celcius.

If the gas cost and consumption doubles for every +5 degrees C of drying temperature then at 70

degrees C, which I have been advised is the chosen ideal temperature to dry at to increase

throughput, then the gas cost assumption would be an increase of $306,000 resulting in a total of

$408,000. p.a.

8659 Litres of gas produces approx. 59747kWhr of energy. Multiply this by 4 (50 degrees C to 70

degrees C) = 239,988 kWhrs – or 240mWhrs. energy. This is equivalent to approx. 240MW Th

energy. We have 1.82MW x 7000 hrs = 12,740 mWTh Thermal to dispose of – so even for allowing

for transmission losses and leaks there is ample thermal energy to use in the kilns … and some.

(Note: these energy comparisons between natural gas calorific LV value and kW Th energy values

needs further analysis)

Revenue and Savings Streams vs. Capital Cost

Description Value

Wood pellets. 3000 Tonnes x $183 profit / Tonne #1 $549,600.00

Briquettes. 1700 Tonnes x $375 / Tonne profit #1 $637,500.00

Exported electrical energy. $478,307.00

Electrical energy savings. $382,550.00

Extra profit from higher throughput. 9000m3 x $25 / m3 $225,000.00

Gas consumption $102,000.00

Total amount: $2,374,957.00

Capital investment: Stage 1 $13,225,000.00