Page 17 - All About History 55 - 2017 UK

P. 17

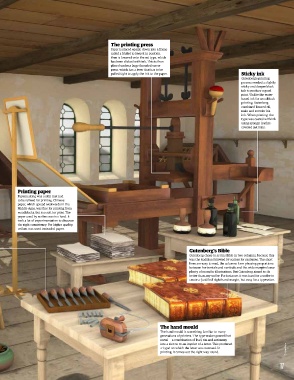

The printing press

Paper is placed upside down into a frame

called a frisket to keep it in position,

then is lowered onto the set type, which

has been slicked with ink. This is then

placed under a large threaded screw

press, which has a lever that has to be

pulled tight to apply the ink to the paper. Sticky ink

Gutenberg’s printing

process needed a slightly

sticky and deeper black

ink to produce a good

print. Unlike the water-

based ink for woodblock

printing, Gutenberg

combined linseed oil,

resin and soot for his

ink. When printing, the

type was coated with ink

using spongy, leather-

covered ink balls.

Printing paper

Papermaking was a skill that had

to be refined for printing. Chinese

paper, which spread westwards in the

Middle Ages, was fine for printing from

woodblocks, but too soft for print. The

paper used by scribes was too hard. It

took a lot of experimentation to discover

the right consistency. For higher quality,

vellum was used instead of paper.

Gutenberg’s Bible

Gutenberg chose to set his Bible in two columns, because this

was the tradition followed by scribes for centuries. The short

lines are easy to read, the columns form pleasing proportions

between horizontals and verticals and the wide margins leave

plenty of room for illustrations. But Gutenberg aimed to do

better than any scribe. For instance, it was hard for a scribe to

create a ‘justified’ right-hand margin, but easy for a typesetter.

The hand mould

The hand mould is something familiar to many

generations of printers. The type-maker poured hot

metal — a combination of lead, tin and antimony —

into a slot on to an imprint of a letter. This produced

a ‘type’ on which the letter was reversed. In © Adrian Mann

printing, it comes out the right way round.

17