Page 10 - July 2019

P. 10

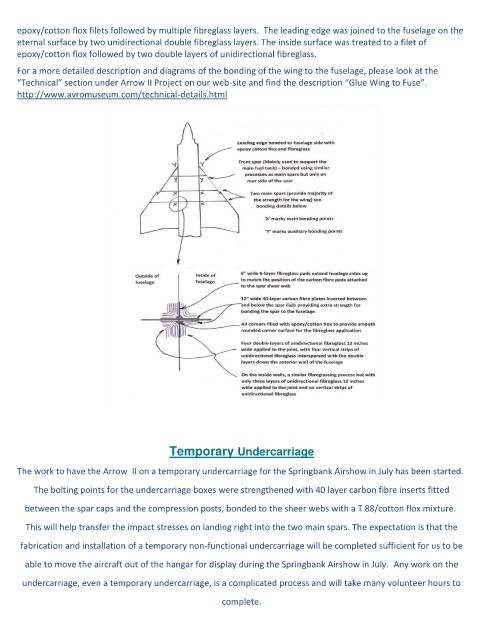

epoxy/cotton flox filets followed by multiple fibreglass layers. The leading edge was joined to the fuselage on the

eternal surface by two unidirectional double fibreglass layers. The inside surface was treated to a filet of

epoxy/cotton flox followed by two double layers of unidirectional fibreglass.

For a more detailed description and diagrams of the bonding of the wing to the fuselage, please look at the

“Technical” section under Arrow II Project on our web-site and find the description “Glue Wing to Fuse”.

http://www.avromuseum.com/technical-details.html

Temporary Undercarriage

The work to have the Arrow II on a temporary undercarriage for the Springbank Airshow in July has been started.

The bolting points for the undercarriage boxes were strengthened with 40 layer carbon fibre inserts fitted

between the spar caps and the compression posts, bonded to the sheer webs with a T 88/cotton flox mixture.

This will help transfer the impact stresses on landing right into the two main spars. The expectation is that the

fabrication and installation of a temporary non-functional undercarriage will be completed sufficient for us to be

able to move the aircraft out of the hangar for display during the Springbank Airshow in July. Any work on the

undercarriage, even a temporary undercarriage, is a complicated process and will take many volunteer hours to

complete.