Page 189 - Wurth Total Catalogue

P. 189

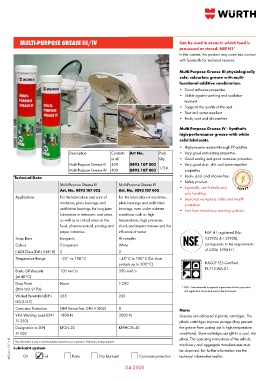

MULTI-PURPOSE GREASE III/IV Can be used in areas in which food is

processed or stored. NSF H1 1

In this context, the product may come into contact

with foodstuffs for technical reasons.

Multi-Purpose Grease III physiologically

safe, colourless grease with multi-

functional additive combination.

• Good adhesive properties.

• Stable against working and oxidation-

resistant.

• Supports the quality of the seal.

• Dust and water-repellent.

• Resin, acid and silicone-free.

Multi-Purpose Grease IV - Synthetic

high-performance grease with white

solid lubricants.

• High-pressure resistant through EP additive.

Description Contents Art No. Pack • Very good anti-seizing properties.

in ml Qty. • Good sealing and good corrosion protection.

Multi-Purpose Grease III 400 0893 107 002 • Very good dust-, dirt- and water-repellent

Multi-Purpose Grease IV 400 0893 107 003 1/24 properties.

Technical Data • Resin-, acid- and silicone-free.

• Safety product.

Multi-Purpose Grease III Multi-Purpose Grease IV • Especially user-friendly and

Art. No. 0893 107 002 Art. No. 0893 107 003 safe handling.

Applications For the lubrication and care of For the lubrication of machines, • Improved workplace safety and health

machines, plain bearings and plain bearings and antifriction protection.

antifriction bearings, for long-term bearings, even under extreme • Free from mandatory warning symbols.

lubrication in wetrooms and areas conditions such as high

as well as in critical areas in the temperatures, high pressures,

food, pharmaceutical, printing and shock and impact stresses and the

paper industries. influence of water. NSF H1 registered (No:

Soap Base Inorganic Al complex 135924 & 135928),

Colour Transparent White corresponds to the requirements

of USDA 1998 H1.

NLGI Class (DIN 51818) 2 2

Temperature Range –20° to 150°C –45°C to 180°C (for short

periods up to 200°C) HACCP FZS Certified:

PE-715-WA-01.

Basic Oil Viscosity 100 mm /s 350 mm /s

2

2

(at 40°C)

Drop Point None > 250

(DIN ISO 2176) 1 NSF = Internationally recognised organisation for the supervision

and registration of products used in the food sector.

Worked Penetration (DIN 285 285

ISO 2137)

Corrosion Protection (SKF Emcor-Test, DIN 51802) 0 Note:

VKA Welding Load (DIN 1800 N 3000 N Greases are delivered in plastic cartridges. The

51350) plastic cartridges improve storage (they prevent

Designation to DIN KP2N-20 KPFHC2R-40 the grease from oozing out in high temperature

51502 conditions). Store cartridges upright in a cool, dry

place. The operating instructions of the vehicle,

AUS. pub. 12/14 © Lubricant system machinery and aggregate manufactu rers must

This information is only a recommendation based on our experience. Preliminary testing required.

be observed. For further information see the

✓

Oil Fat Paste Dry lubricant Corrosion protection

technical information leaflet.

04 2505