Page 57 - Wurth Total Catalogue

P. 57

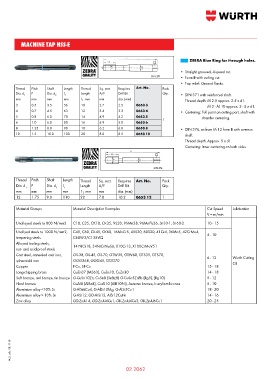

machine tap hss-e

ZEBRA Blue Ring for through holes.

• Straight grooved, 4-speed cut.

• Form B with curling cut.

• Tap relief: Ground flanks.

Thread Pitch Shaft Length Thread Sq. sect. Requires Art. No. Pack

Dia. d P Dia. d l Length A/F Drill Bit Qty.

1 2 1 • DIN 371 with reinforced shaft.

mm mm mm mm l 2 mm mm dia. (mm) Thread depth: M 2.5 approx. 2.5 x d1.

3 0.5 3.5 56 10 2.7 2.5 0653 3 M 3 - M 10 approx. 3 - 5 x d1.

4 0.7 4.5 63 12 3.4 3.3 0653 4 • Centering: Full point on cutting part, shaft with

5 0.8 6.0 70 14 4.9 4.2 0653 5 1 chamfer centering.

6 1.0 6.0 80 16 4.9 5.0 0653 6

8 1.25 8.0 90 18 6.2 6.8 0653 8 • DIN 376, as from M 12 form B with overrun

10 1.5 10.0 100 20 8.0 8.5 0653 10 shaft.

Thread depth: Approx. 5 x d1.

Centering: Inner centering on both sides.

Thread Pitch Shaft Length Thread Sq. sect. Requires Art. No. Pack

Dia. d P Dia. d l Length A/F Drill Bit Qty.

1 2 1

mm mm mm mm 1 2 mm mm dia. (mm)

12 1.75 9.0 110 22 7.0 10.2 0653 12 1

Material Groups Material Description Examples Cut Speed Lubrication

V = m/min

Unalloyed steels to 800 N/mm2 C10, C35, CK10, CK35, 9S20, 9SMn28, 96MnPb36, St 33-1, St 60-2 10 - 15

Unallyed steels to 1000 N/mm2, C45, C60, CK45, CK60, 16MnCr5, 45S20, 60S20, 41Cr4, 36Mn5, 42CrMo4,

tempering steels C60W3/C135W2 4 - 10

Alloyed tooling steels, 14 NiCr18, 54NiCrMoS6, X10Cr13, X100CrMoV51

rust- and acid-proof steels

Cast steel, annealed cast iron, GS-38, GS-45, GS-70, GTW35, GTW60, GTS35, GTS70,

spheroidal iron GGG368, GGG45, GGG70 6 - 12 Wurth Cutting

Copper F-Cu, SF-Cu 15 - 18 Oil

Long-chipping brass CuZn37 (MS63), CuZn10, CuZn30 14 - 18

Soft bronze, red bronze, tin bronze G-CuSn10Zn, CuSn8 (SnBz8) G-CuSn5ZnPb (Rg5), (Rg10) 5 - 12

Hard bronze CuAl8 (AlBz8), CuAl10 (AlB10Ni), Aeterna bronze, b erylium bronze 5 - 10

Aluminium alloy <10% Si G-AlSi6Cu4, G-AlSi10Mg, G-AlSi5Cu1 18 - 20

Aluminium alloy > 10% Si G-ASi12, GD-AISi12, AlSi12CuNi 14 - 16

Zinc alloy GD-ZnA14, GD-ZnAl4Cu1, GK-ZnAl4Cu3, GK-ZnAl6Cu1 20 - 25

AUS. pub. 08/11 ©

02 2062