Page 58 - Wurth Total Catalogue

P. 58

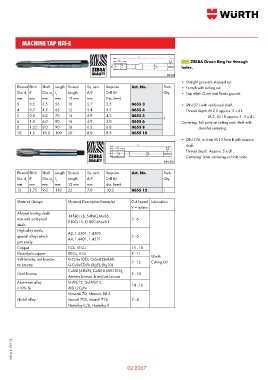

machine tap hss-e

ZEBRA Green Ring for through

holes.

• Straight grooved, 4-speed cut.

Thread Pitch Shaft Length Thread Sq. sect. Requires Art. No. Pack. • Form B with curling cut.

Dia. d P Dia. d l Length A/F Drill Bit Qty. • Tap relief: Outer and flanks ground.

1 2 1

mm mm mm mm 12 mm mm Dia. (mm)

3 0.5 3.5 56 10 2.7 2.5 0655 3 • DIN 371 with reinforced shaft.

4 0.7 4.5 63 12 3.4 3.3 0655 4 Thread depth: M 2.5 approx. 2 x d1.

5 0.8 6.0 70 14 4.9 4.2 0655 5 1 M 3 - M 10 approx 3 - 5 x d1.

6 1.0 6.0 80 16 4.9 5.0 0655 6 Centering: Full point on cutting part, shaft with

8 1.25 8.0 90 18 6.2 6.8 0655 8 chamfer centering.

10 1.5 10.0 100 20 8.0 8.5 0655 10

• DIN 376, as from M 12 form B with overrun

shaft.

Thread depth: Approx. 5 x d1.

Centering: Inner centering on both sides.

Thread Pitch Shaft Length Thread Sq. sect. Requires Art. No. Pack.

Dia. d P Dia. d l 1 Length A/F Drill Bit Qty.

1

2

mm mm mm mm 12 mm mm dia. (mm)

12 1.75 9.0 110 22 7.0 10.2 0655 12 1

Material Groups Material Description Examples Cut Speed Lubrication

V = m/min

Alloyed tooling steels

rust- and acid-proof 14NiCr18, 54NiCrMo56, 3 - 6

X10Cr13, X100CrMoV51

steels

High alloy steels,

special alloys which A2: 1.4301, 1.4305 3 - 6

jam easily A4: 1.4401, 1.4571

Copper F-Cu, SF-Cu 15 - 18

Electrolytic copper KE-Cu, E-Cu 8 - 11

Soft bronze, red bronze, G-CuSn10Zn, CuSn8 (SnBz8) Wurth

Cutting Oil

tin bronze G-CuSn5ZnPb (Rg5), (Rg10) 5 - 12

CuAl8 (AlBz8), CuAl10 (AlB10Ni),

Hard bronze 5 - 10

Aeterna bronze, b erylium bronze

Aluminium alloy G-AlSi12, Gd-AlSi12,

>10% Si AlSi12CuNi 14 - 16

Nimonic 70, Nimonic 80 A

Nickel alloy Inconel 700, inconel 718 2 - 4

Hastelloy C/B, Hastelloy X

AUS. pub. 08/11 ©

02 2067