Page 339 - Foton Workshop Manual - Tunland (AT)

P. 339

DIAGNOSTICS - ENGINE CONTROL SYSTEM 04-193

NOTICE

• To implement the following steps, ensure that ECM is grounded properly.

• Before conducting electric diagnosis, do refer to the reference circuit diagram

and the element information.

• Before conducting measurement, check the pins of connectors for rupture,

04

looseness and rust, and ensure that the pins are contacted properly.

• If the connection is good, check the sensor signal voltage when moving the

connector and harness. If a fault occurs, the voltage display on the diagnostic

instrument will change.

• injector connector is in poor contact and the wiring harness is broken or shorted

• Four cylinder injector inspection methods are the same, take 1 cylinder as an

example for inspection

1 . DTC inspection

(a) Ignition switch: OFF.

(b) Connect the diagnostic apparatus.

(c) Use the diagnostic apparatus, read the fault code.

(d) Confirm whether there is fault code related to injector?

Is the inspection result normal?

YES>To step 2.

NO>Intermittent trouble exists.

2 . Check the wire harness for the 1 cylinder injector

(a) Ignition switch: OFF.

(b) Disconnect the battery negative cable.

(c) Disconnect the 1 cylinder injector connector E12.

(d) Disconnect connector E01 of ECM.

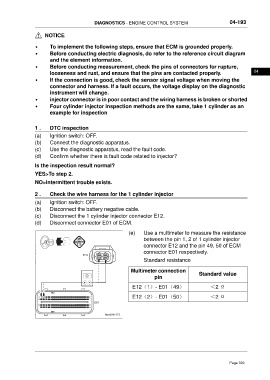

(e) Use a multimeter to measure the resistance

between the pin 1, 2 of 1 cylinder injector

connector E12 and the pin 49, 50 of ECM

connector E01 respectively.

Standard resistance

Multimeter connection

Standard value

pin

E12(1)- E01(49) <2 Ω

E12(2)- E01(50) <2 Ω

Page 339