Page 530 - Foton Workshop Manual - Tunland (AT)

P. 530

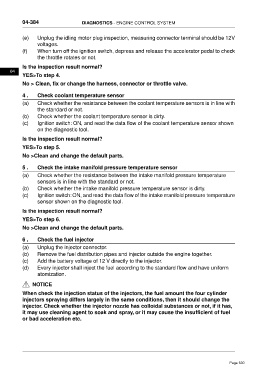

04-384 DIAGNOSTICS - ENGINE CONTROL SYSTEM

(e) Unplug the idling motor plug inspection, measuring connector terminal should be 12V

voltages.

(f) When turn off the ignition switch, depress and release the accelerator pedal to check

the throttle rotates or not.

Is the inspection result normal?

04

YES>To step 4.

No > Clean, fix or change the harness, connector or throttle valve.

4 . Check coolant temperature sensor

(a) Check whether the resistance between the coolant temperature sensors is in line with

the standard or not.

(b) Check whether the coolant temperature sensor is dirty.

(c) Ignition switch: ON, and read the data flow of the coolant temperature sensor shown

on the diagnostic tool.

Is the inspection result normal?

YES>To step 5.

No >Clean and change the default parts.

5 . Check the intake manifold pressure temperature sensor

(a) Check whether the resistance between the intake manifold pressure temperature

sensors is in line with the standard or not.

(b) Check whether the intake manifold pressure temperature sensor is dirty.

(c) Ignition switch: ON, and read the data flow of the intake manifold pressure temperature

sensor shown on the diagnostic tool.

Is the inspection result normal?

YES>To step 6.

No >Clean and change the default parts.

6 . Check the fuel injector

(a) Unplug the injector connector.

(b) Remove the fuel distribution pipes and injector outside the engine together.

(c) Add the battery voltage of 12 V directly to the injector.

(d) Every injector shall inject the fuel according to the standard flow and have uniform

atomization.

NOTICE

When check the injection status of the injectors, the fuel amount the four cylinder

injectors spraying differs largely in the same conditions, then it should change the

injector. Check whether the injector nozzle has colloidal substances or not, if it has,

it may use cleaning agent to soak and spray, or it may cause the insufficient of fuel

or bad acceleration etc.

Page 530