Page 332 - Foton Workshop Manual - Sauvana

P. 332

12B-42 ENGINE MECHANICAL - ENGINE ASSEMBLY

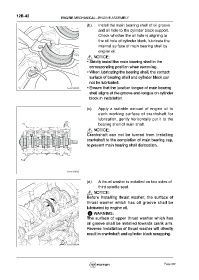

(b). Install the main bearing shell of oil groove

and oil hole to the cylinder block support.

Check whether the oil hole is aligning to

the oil hole of cylinder block, lubricate the

internal surface of main bearing shell by

engine oil.

NOTICE:

• Strictly install the main bearing shell in the

corresponding position when removing.

• When lubricating the bearing shell, the contact

surface of bearing shell and cylinder block can

not be lubricated.

• Ensure that the location tongue of main bearing

shell aligns at the groove-and-tongue on cylinder

block in installation.

(c). Apply a suitable amount of engine oil to

each working surface of crankshaft for

lubrication, gently horizontally put it to the

bearing shell of main shaft.

NOTICE:

Crankshaft can not be turned from installing

crankshaft to the completion of main bearing cap,

to prevent main bearing shell dislocation.

(d). A thrust washer is installed on two sides of

third spindle seat.

NOTICE:

Before installing thrust washer, the surface of

thrust washer which has oil groove shall be

lubricated by engine oil.

WARNING:

The surface of upper thrust washer which has

oil groove shall be installed towards crank arm.

Reverse installation of thrust washer will directly

result in crankshaft and cylinder block scrapping.

Page 332