Page 334 - Foton Workshop Manual - Sauvana

P. 334

12B-44 ENGINE MECHANICAL - ENGINE ASSEMBLY

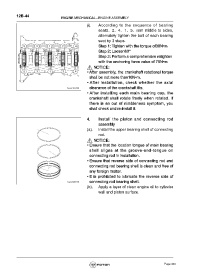

(i). According to the sequence of bearing

seat3、2、4、1、5、rom middle to sides,

alternately tighten the bolt of each bearing

seat by 3 steps.

Step 1: Tighten with the torque of30N•m

Step 2: Loosen60°

Step 3: Perform a comprehensive retighten

with the anchoring force value of 78N•m

NOTICE:

• After assembly, the crankshaft rotational torque

shall be not more than10N•m.

• After installation, check whether the axial

clearance of the crankshaft fits.

• After installing each main bearing cap, the

crankshaft shall rotate freely when rotated. If

there is an out of nimbleness symptom, you

shall check and re-install it.

4. Install the piston and connecting rod

assembly

(a). Install the upper bearing shell of connecting

rod.

NOTICE:

• Ensure that the location tongue of main bearing

shell aligns at the groove-and-tongue on

connecting rod in installation.

• Ensure that reverse side of connecting rod and

connecting rod bearing shell is clean and free of

any foreign matter.

• It is prohibited to lubricate the reverse side of

connecting rod bearing shell.

(b). Apply a layer of clean engine oil to cylinder

wall and piston surface.

Page 334