Page 978 - Workshop Manual - Tunland (2017)

P. 978

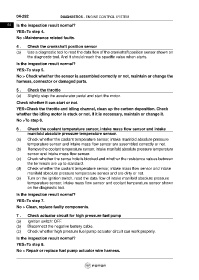

04-292 DIAGNOSTICS - ENGINE CONTROL SYSTEM

04 Is the inspection result normal?

YES>To step 4.

No >Maintenance related faults.

4 . Check the crankshaft position sensor

(a) Use a diagnostic tool to read the data flow of the crankshaft position sensor shown on

the diagnostic tool. And it should reach the specific value when starts.

Is the inspection result normal?

YES>To step 5.

No > Check whether the sensor is assembled correctly or not, maintain or change the

harness, connector or damaged parts.

5 . Check the throttle

(a) Slightly step the accelerator pedal and start the motor.

Check whether it can start or not.

YES>Check the throttle and idling channel, clean up the carbon deposition. Check

whether the idling motor is stuck or not, if it is necessary, maintain or change it.

No >To step 6.

6 . Check the coolant temperature sensor, intake mass flow sensor and intake

manifold absolute pressure temperature sensor.

(a) Check whether the coolant temperature sensor, intake manifold absolute pressure

temperature sensor and intake mass flow sensor are assembled correctly or not.

(b) Remove the coolant temperature sensor, intake manifold absolute pressure temperature

sensor and intake mass flow sensor.

(c) Check whether the sense hole is blocked and whether the resistance values between

the terminals are up to standard.

(d) Check whether the coolant temperature sensor, intake mass flow sensor and intake

manifold absolute pressure temperature sensor and are dirty or not.

(e) Turn on the ignition switch, read the data flow of intake manifold absolute pressure

temperature sensor, intake mass flow sensor and coolant temperature sensor shown

on the diagnostic tool.

Is the inspection result normal?

YES>To step 7.

No > Clean, replace faulty components.

7 . Check actuator circuit for high pressure fuel pump

(a) Ignition switch: OFF.

(b) Disconnect the negative battery cable.

(c) Check whether high pressure fuel pump actuator circuit can work properly.

Is the inspection result normal?

YES>To step 8.

No > Repair or replace fuel pump actuator wire harness.