Page 19 - 0917 - Finlay Group Conveyor Magazine Issue 3

P. 19

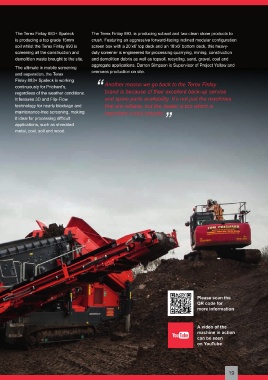

OUTPUT BOOST The Terex Finlay 883+ Spaleck The Terex Finlay 893, is producing subsoil and two clean stone products to

crush. Featuring an aggressive forward-facing inclined modular configuration

is producing a top grade 15mm

soil whilst the Terex Finlay 893 is

screen box with a 20’x6’ top deck and an 18’x6’ bottom deck, this heavy-

duty screener is engineered for processing quarrying, mining, construction

screening all the construction and

FOR CONTRACTING FIRM demolition waste brought to the site. and demolition debris as well as topsoil, recycling, sand, gravel, coal and

aggregate applications. Darren Simpson is Supervisor of Project Yellow and

The ultimate in mobile screening

oversees production on site.

and separation, the Terex

Finlay 883+ Spaleck is working

continuously for Prichard's,

Prichard's, a South West based has taken delivery of a Terex Finlay Prichard, Director, worked with Finlay regardless of the weather conditions. “ Another reason we go back to the Terex Finlay

brand is because of their excellent back-up service

demolition and plant hire company, 883+ Spaleck and a Terex Finlay 893 SW to specify the two additional units It features 3D and Flip-Flow and spare parts availability. It’s not just the machines

has reported a boom in production and has since seen an increase in its which brings his fleet of Terex Finlay technology for nearly blockage and that are reliable, but the dealer is too which is

after the arrival of new plant from soil and stone production at its Project plant up to ten units in total. maintenance-free screening, making

Finlay Plant SW. Over the last six Yellow site in Pontyclun, one of the it ideal for processing difficult important in this industry. ”

months the firm, based in Llantrisant, company’s four recycling yards. Tom applications, such as shredded

“ We have grown to become one of the leading suppliers of construction and support metal, coal, soil and wood.

services throughout Wales, the Midlands and the South West and we rely on our

machines to provide quality, cost-effective solutions for our customers. The new

plant will enable us to increase our productivity still further. Our operators are very

”

happy with the units – if they’re happy, so are we.

Please scan the

QR code for

more information

A video of the

machine in action

can be seen

CUSTOMERS 18 19

on YouTube