Page 8 - 0917 - Finlay Group Conveyor Magazine Issue 3

P. 8

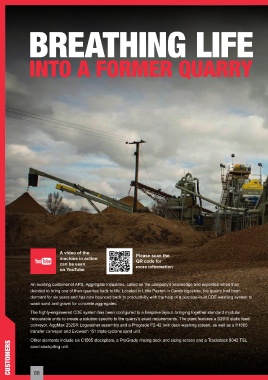

BREATHING LIFE

INTO A FORMER QUARRY

A video of the Please scan the

machine in action QR code for

can be seen

on YouTube more information

An existing customer of APS, Aggregate Industries, called on the company’s knowledge and expertise when they Duncan Hayden, assistant site manager at Little Paxton Quarry, is very happy with the solution, which is based on a

decided to bring one of their quarries back to life. Located in Little Paxton in Cambridgeshire, the quarry had been ‘price per tonne’ contract;

dormant for six years and has now bounced back to productivity with the help of a purpose-built CDE washing system to

wash sand and gravel for concrete aggregates. “ As a company we’ve been working with APS for around ten years and they always

The highly-engineered CDE system has been configured to a bespoke layout, bringing together standard modular come up with the goods without fail. On this site they specified each of the components

relocatable units to create a solution specific to the quarry’s exact requirements. The plant features a S2910 static feed to work in tune with each other to deliver maximum performance for us. The plant

conveyor, AggMax 252SR Logwasher assembly and a Prograde P2-42 twin deck washing screen, as well as a H1565 had to be designed to comply with stringent guidelines because of its close proximity

transfer conveyor and Evowash 151 triple cyclone sand unit. to Paxton Pits Nature Reserve, a site of special scientific interest (SSSI). This included

Other elements include six C1565 stockpilers, a ProGrade rinsing deck and sizing screen and a Trackstack 8042 TSL specific heights and noise restrictions as well as a special ‘Moorlands Green’ colour

CUSTOMERS 08 ” 09

coating designed to blend with the environment. Nothing was too much trouble.

sand stockpiling unit.