Page 24 - Personal Study Notes (Engineering Metrology - 22342)

P. 24

Page 24 of 176

3. For taking accurate measurement of deformation such as intension and compression.

4. To determine positional errors of surfaces such as parallelism, squareness and

alignment.

5. To check the alignment of lathe centers by using suitable accurate bar between the

centers.

6. To check trueness of milling machine arbours and to check the parallelism of shaper

arm with table surface or vice.

Q. State the difference between direct and comparison measurements.

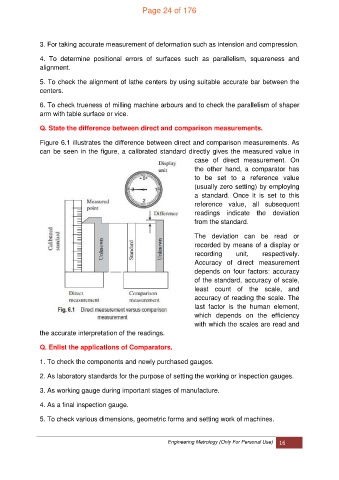

Figure 6.1 illustrates the difference between direct and comparison measurements. As

can be seen in the figure, a calibrated standard directly gives the measured value in

case of direct measurement. On

the other hand, a comparator has

to be set to a reference value

(usually zero setting) by employing

a standard. Once it is set to this

reference value, all subsequent

readings indicate the deviation

from the standard.

The deviation can be read or

recorded by means of a display or

recording unit, respectively.

Accuracy of direct measurement

depends on four factors: accuracy

of the standard, accuracy of scale,

least count of the scale, and

accuracy of reading the scale. The

last factor is the human element,

which depends on the efficiency

with which the scales are read and

the accurate interpretation of the readings.

Q. Enlist the applications of Comparators.

1. To check the components and newly purchased gauges.

2. As laboratory standards for the purpose of setting the working or inspection gauges.

3. As working gauge during important stages of manufacture.

4. As a final inspection gauge.

5. To check various dimensions, geometric forms and setting work of machines.

Engineering Metrology (Only For Personal Use) 16